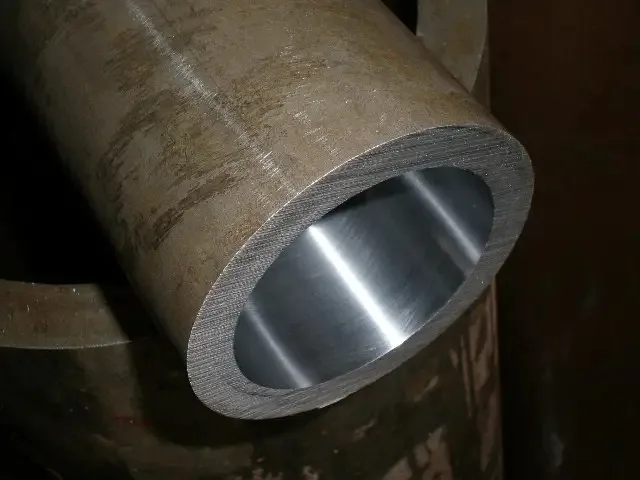

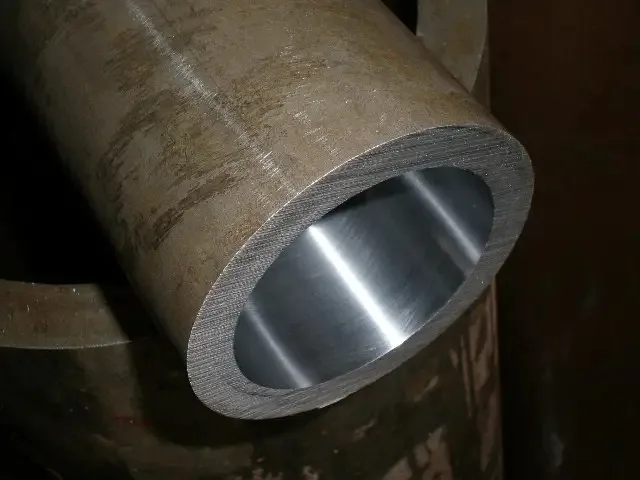

Precision cylinder honing tube

Precision oil cylinder honing tube is a high-precision seamless steel tube made by cold drawing or cold rolling process, mainly used in the manufacturing of mechanical components such as hydraulic oil cylinders and air cylinders.

Core Features

High precision machining

The inner diameter tolerance can be controlled within 0.02-0.05mm, with a surface roughness of Ra ≤ 0.08 μ m and a straightness ≤ 0.3mm/m, meeting the accuracy requirements of H5-H10 levels

Diverse materials

Common materials include 20 # and 45 # carbon steel, 16Mn alloy steel, 27SiMn, and 304/316 stainless steel, which are suitable for different pressure and corrosion resistance requirements

Wear resistant and pressure resistant

The honing process forms a cold work hardening layer, which improves the wear resistance of the inner wall, can withstand high-pressure fluid transmission (such as hydraulic systems), and is resistant to deformation

application

Hydraulic system: cylinder barrel, cylinder barrel, hydraulic pipe for construction machinery

Industrial equipment: petroleum machinery, automotive precision components, pharmaceutical equipment pipelines

Special scenarios: food processing (sanitary grade), ship hydraulic systems (corrosion-resistant)

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.