Aluminum alloy forging process characteristics

One, pulse multi-directional forging

1, aluminum alloy radial forging hammer forging more than one direction of the embryo material, so that the deformation of the metal is in the state of compressive stress;

2, is conducive to the improvement of the plasticity of the metal, can reduce and eliminate the radial tensile stress on the cross-section of the embryonic material;

3, the hammer head pulse loading frequency is high, up to hundreds or even more per minute, which can effectively limit the lateral flow of the metal and improve its axial elongation;

4, Since the metal has high process plasticity, it can be cold forged;

5, for low plasticity alloy, pulse loading forging process than continuous loading plasticity increased 2.5 ~ 3 times.

Second, small compression, fast forging speed

1, aluminum alloy radial forging loading mode for each forging compression is small, fast;

2, in the metal deformation zone, the deformation amount is small, the metal movement is small, the movement distance is short;

3, reduce the friction coefficient of metal in deformation, reduce friction resistance, make the deformation uniform, easier to go deep inside;

4, aluminum alloy forgings deformation resistance is small, can reduce the tonnage of equipment, improve the service life of the tool.

Third, precision forging process

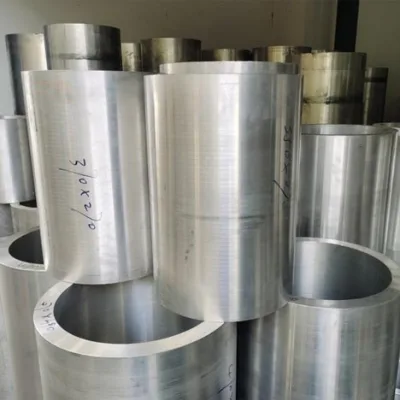

1, aluminum alloy radial die forging forgings large size, high dimensional accuracy, surface roughness value is small;

2, the current domestic radial forging machine can be forged on the solid shaft diameter of φ400mm, hollow shaft outer diameter of φ600mm, length of 6000mm;

3, forging parts forged on roller type rotary forging machine, diameter from φ150mm (solid) to OD φ320mm (hollow parts);

4, hot forging parts size accuracy can reach 6~7 level, cold forging parts size accuracy can reach 2~4 level;

5, aluminum alloy radial forging process is usually called precision forging, the raw material requirements are also higher.

Fourth, high efficiency and mass production

1, due to the high degree of automation of aluminum alloy radial forging machine, adjustment, on, off the material, forging the whole process can be automatically controlled, easy to operate, and high frequency, so the production efficiency is high;

2, the hammer head shape is simple, adaptable, change products, short adjustment time, suitable for a variety of batch and specialized production.

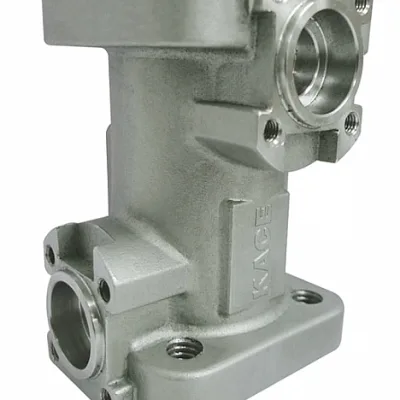

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.