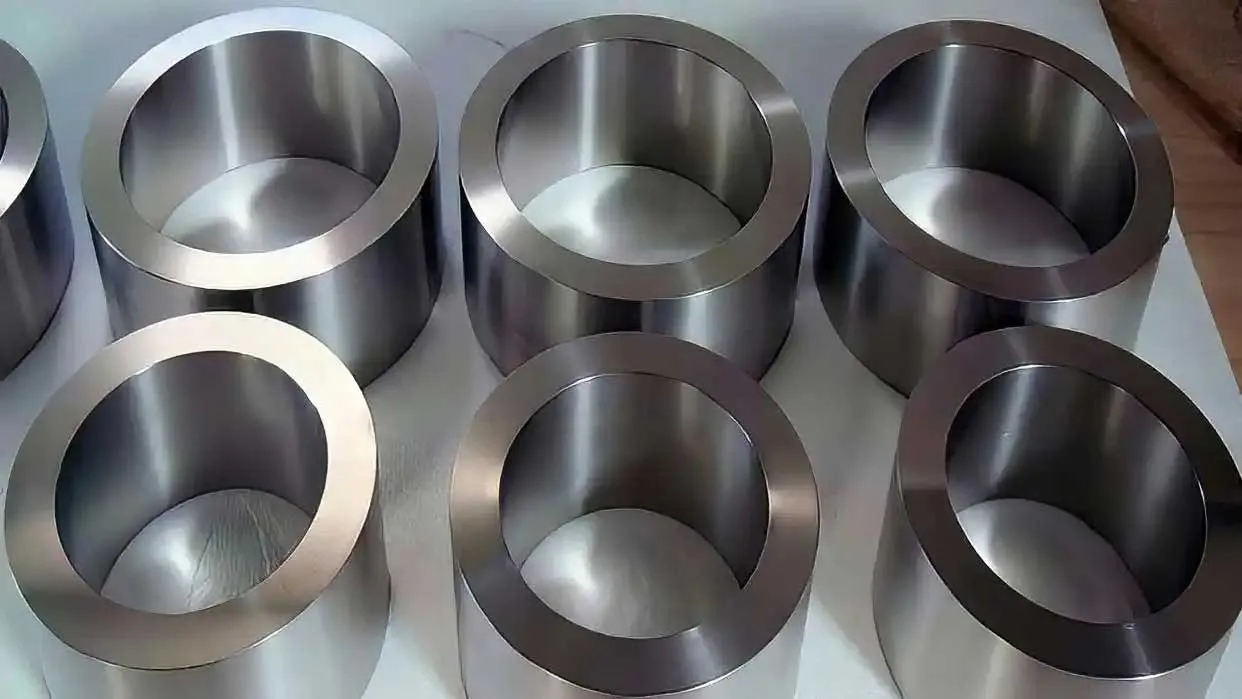

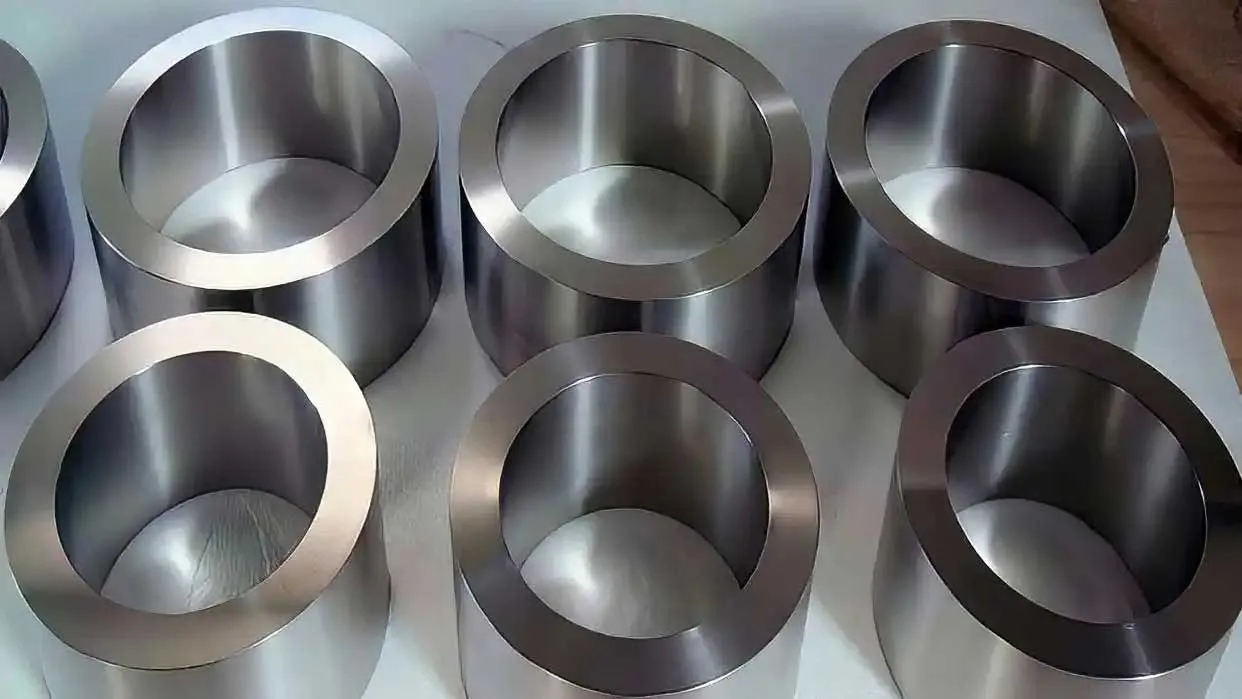

Aluminum Ring Forgings

Products or semi-finished products obtained by forging metal billets.

Aluminum ring forgings refer to finished or semi-finished products made by applying pressure to metal billets through a forging process, causing plastic deformation, thereby changing their shape, size, and microstructure to suit specific applications.

Product Advantages

Forging optimizes the microstructure and mechanical properties of aluminum ring forgings.

Aluminum ring forgings exhibit excellent precision, high output, superior toughness, efficient production, and accuracy.

Product Structure

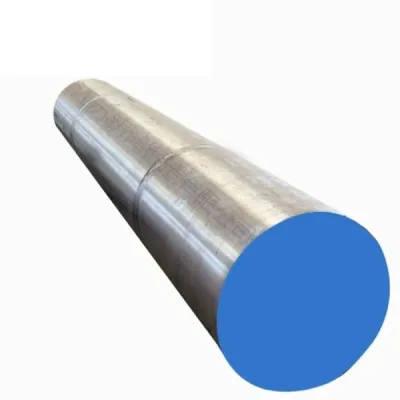

1. Solid Forgings: These forgings are made from solid metal blocks through a forging process. They come in various shapes, from simple cylinders and cubes to complex geometries.

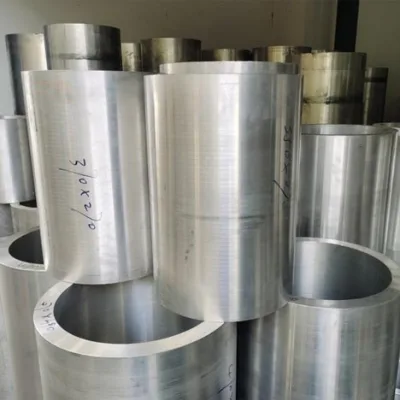

2. Hollow Forgings: Unlike solid forgings, these forgings are hollow inside. They are mainly used for components requiring weight reduction or internal channels, such as pipes and ring-shaped components.

3. Stepped Forgings: These forgings have inconsistent cross-sectional dimensions and are often used to connect components of different sizes, such as shafts.

4. Toothed Forgings: Forgings with gear teeth, suitable for manufacturing gears and other transmission components.

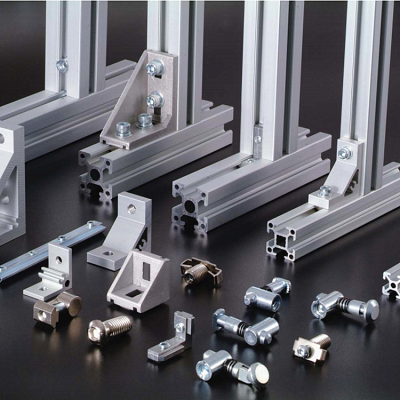

5. Flange Forgings: Forgings with flanges, used for pipe connections or as support structures.

6. Impeller Forgings: Used to manufacture impellers for rotating machinery such as turbines and pumps.

7. Crankshaft Forgings: Used in engines and other machinery, with complex shapes and multiple cranks.

8. Connecting Rod Forgings: Forgings connecting the piston and crankshaft, typically with complex shapes and diverse sizes.

9. Gear Shaft Forgings: Forgings that integrate gears and shafts, suitable for transmitting torque and withstanding bending loads.

10. Annular Forgings: Forgings with an annular structure, typically used for bearing housings, seals, etc. After forging, aluminum ring forgings can effectively remove the porosity and voids inside the metal, significantly enhancing their mechanical properties. Therefore, they are widely used in fields such as power, automobile manufacturing, pressure vessels, military production, and manufacturing.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.