Hydraulic cylinder solution

Hydraulic cylinder is a key power component in heavy machinery and industrial systems that converts hydraulic energy into linear motion. At Weifu Forging Company, we produce precision forged hydraulic cylinders that possess excellent mechanical strength, sealing reliability, and corrosion resistance. Through integrated processes such as forging, CNC machining, heat treatment, and surface treatment, each component can achieve high-precision dimensions and long-lasting durability, ensuring stable operation even under high pressure and high load conditions.

The hydraulic cylinder forging process is made by deforming the heated metal under controlled pressure to refine its grain structure. Unlike cast or welded hydraulic cylinders, forged hydraulic cylinders eliminate internal voids and impurities, thereby producing stronger and more reliable components. This process ensures a uniform microstructure and optimal fatigue resistance, making forged hydraulic cylinders an ideal choice for building, mining, and marine systems that require high power and durability.

The forging process includes:

Hot forging - forging a heated alloy steel or carbon steel billet into a cross-section that conforms to the design stress distribution under controlled pressure. This step can refine the grain structure and improve the core strength.

Heat treatment - Each forging billet must undergo normalizing, quenching, and tempering treatment to balance hardness and ductility, improve fatigue resistance, and overall durability.

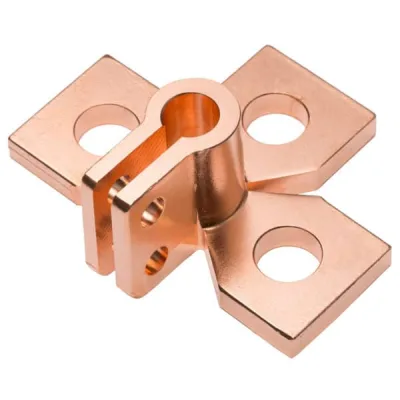

Numerical Control Machining - Precision machining ensures tight alignment of apertures, precise machining of threads, and smoothness of sealing surfaces. This ensures efficient movement and leak free operation.

Surface treatment - using final coatings such as chrome plating, nickel plating, or phosphating to enhance corrosion resistance and wear resistance, especially suitable for cylinders used in high humidity or saltwater environments.

Inspection and Testing - Prior to shipment, ultrasonic, dimensional, and hardness testing will be conducted to verify structural integrity and compliance with ISO 9001:2015 standards.

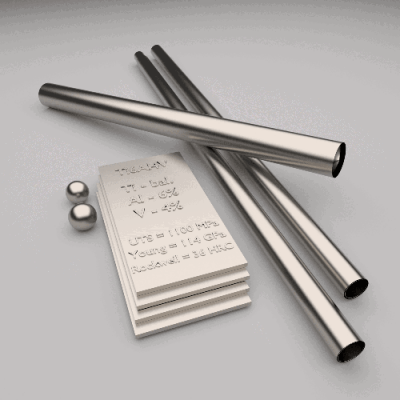

Material selection and customization

We carefully select high-quality steels such as 42CrMo4, 20MnV6, and 16MnCr5, which are renowned for their outstanding strength, impact resistance, and machinability. Each steel grade is precisely matched with the working pressure, temperature, and operating conditions of the hydraulic system.

The size of the oil cylinder, piston rod design, sealing structure, and protective coating can all be fully customized to ensure perfect compatibility with various applications. This adaptability enables Weforging to provide safe, efficient, and high-performance solutions for industries such as mobile hydraulics, energy, and marine engineering.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.