Cold drawn steel pipe factory

Cold drawn steel pipes have become core materials in fields such as mechanical manufacturing and automotive industry due to their high precision, excellent mechanical properties, and wide applicability.

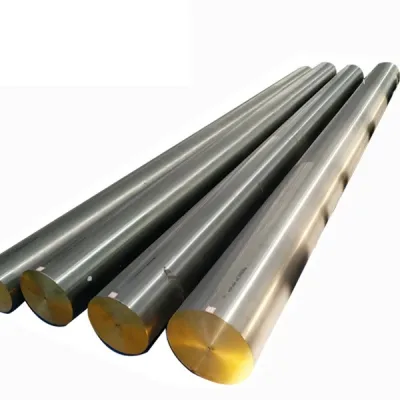

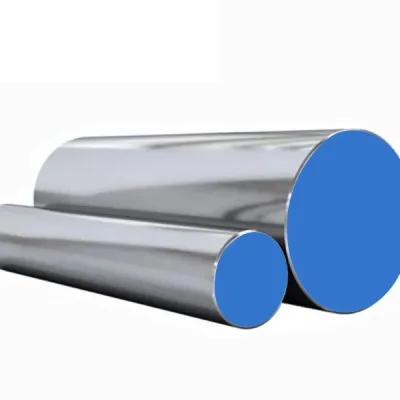

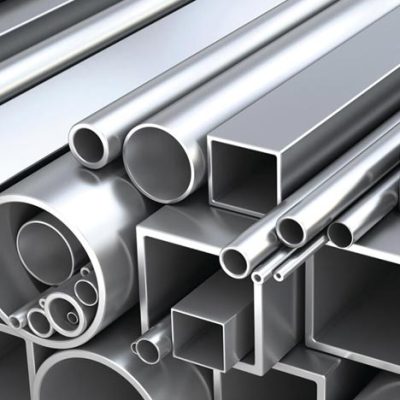

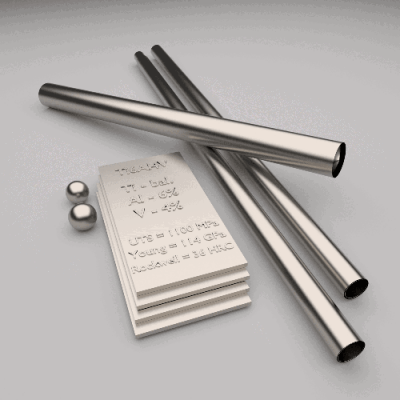

Cold drawn steel pipe refers to seamless steel pipes produced through cold drawing processing technology. This process is to pull the hot rolled or extruded capillary tube through a specific mold at room temperature to achieve the predetermined outer diameter and wall thickness, while improving its surface quality and mechanical properties. Compared with hot-rolled pipes, cold drawn pipes usually have the characteristics of high dimensional accuracy, good surface smoothness, and superior mechanical strength.

Core performance characteristics and application fields of cold drawn steel pipes

Based on its unique processing technology, cold drawn steel pipes exhibit various advantages, which support their wide application.

1. High precision and excellent surface. The cold drawing process can produce steel pipes with a very small tolerance range for outer diameter and wall thickness, and the smoothness of the inner wall is also better than that of hot-rolled pipes.

2. Excellent mechanical performance. Through cold deformation processing and subsequent heat treatment, the tensile strength and yield strength of cold drawn steel pipes are usually higher than those of hot-rolled pipes of the same material, with better comprehensive mechanical properties and the ability to withstand higher pressures or loads.

3. Wide applicability. By adjusting the process parameters, cold drawn steel pipes of different specifications, materials, and performance levels can be produced to meet diverse needs.

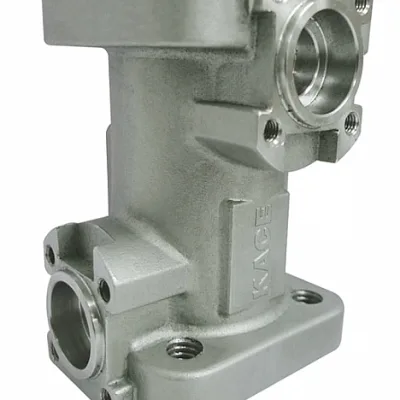

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.