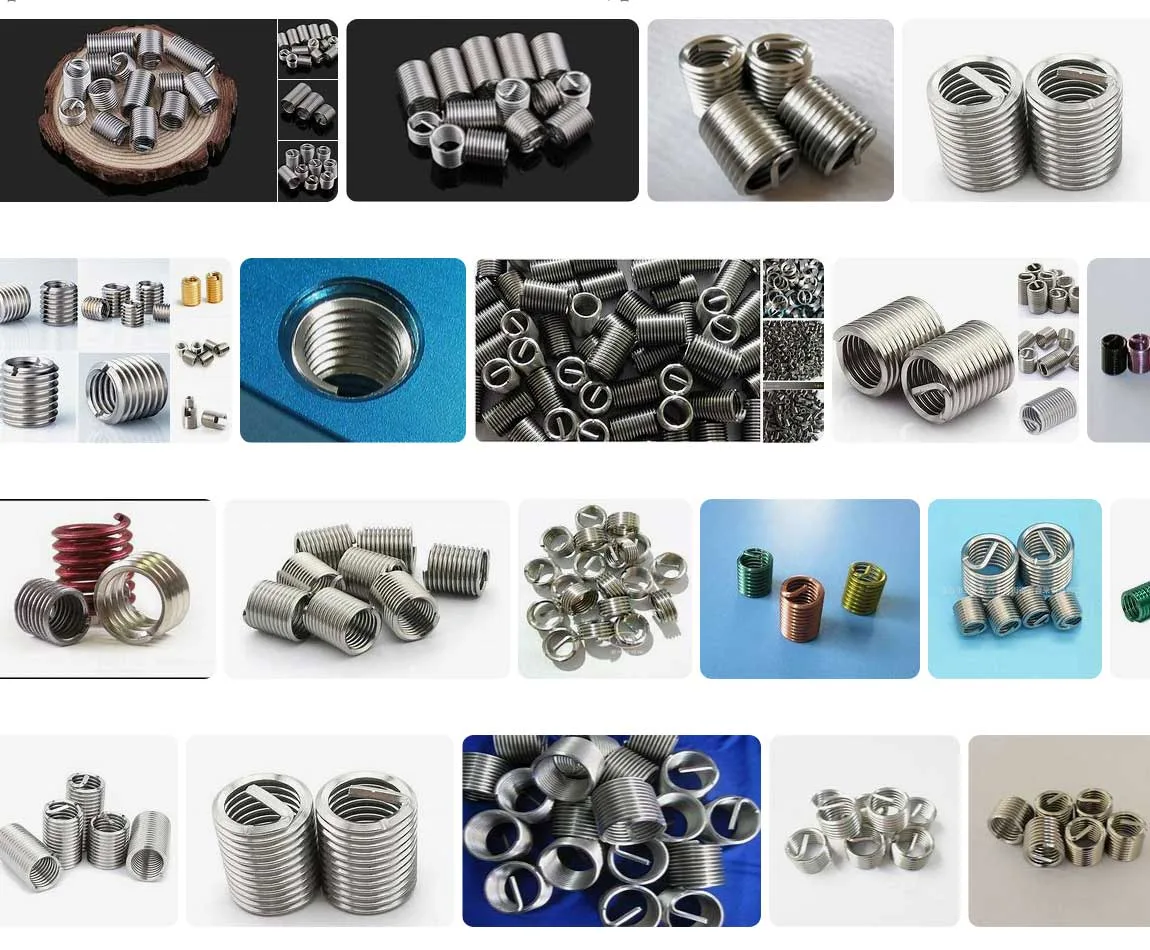

Wire thread inserts

Wire inserts, also known as wire thread inserts, thread inserts, thread bushings, thread protectors, or thread sleeves, are inserts developed to protect threaded holes in non-ferrous metals. They are made of cold-rolled stainless steel wire into a spiral, concentric coil of threads with a diamond-shaped cross-section, similar to a coil spring. Wire inserts can improve thread fatigue strength, reduce wear and corrosion resistance, and thus extend the life of the threaded hole.

Applications of Wire Thread Inserts

1. Enhance connection strength and improve connection conditions.

2. Wear resistance.

3. Increase the load-bearing surface.

4. Prevent loosening.

5. Facilitate maintenance.

Material of Wire Thread Inserts

1. Stainless steel material (304/316L stainless steel, Nitronic 60 stainless steel)

2. High temperature alloys (Inconel X750, Nimonic90)

3. Copper alloy and phosphor bronze

American Standard

MS 122076 Series,Inserl,corrosion resistant.Helical coil,coarse thread.

MS 124651 Series,insert,corrosion resistant.Helical coil,fine thread.

Ms 21209 Series,Insert,screw thread,screw locking.

MIL-1-8846 C,Insert,screw thread.screw locking.

MIL-1-8846 C,Insert,screw thread.Helical coil.

MA 3329,3330,3331,Metric screw locking series.

MA 3279,3280,3281,Metric free running series.

MA 1565,1567,Metric tree running and screw locking,assembly dimensions.

MS 33537 Revision E,Assembly dimensions for screw thread inserts.

British Standards

BS 43377,BS7751,BS7752,BS7753

AS 6733 Series,AS 8455 Series,AGS 3600 Series,AGS 3700 Series

German standards

DIN8140 Part 1,Wire thread inserts for ISO metric screw threads. LN 9499 LN 9039.

| Specifications of Wire thread inserts | |||||

|

d×p |

k×d |

L(mm) |

do(mm) |

Dz(mm) |

N(≈) |

| M2×0.4 | 1d 1.5d 2d |

2 3 4 |

2 | 2.6-2.8 | 2.9 4.7 6.5 |

| M2.5×0.45 | 1d 1.5d 2d |

2.5 3.75 5 |

2.6 | 3.3-3.5 | 3.5 5.9 8.1 |

| M3×0.5 | 1d 1.5d 2d |

3 4.5 6 |

3.1 | 3.8-4.0 | 4 6.3 8.7 |

| M4×0.7 | 1d 1.5d 2d |

4 6 8 |

4.1 | 5.15-5.35 | 3.7 6 8.4 |

| M5×0.8 | 1d 1.5d 2d |

5 7.5 10 |

5.2 | 6.35-6.6 | 4.3 6.9 9.7 |

| M6×1 | 1d 1.5d 2d |

6 9 12 |

6.2 | 7.6-7.85 | 4.2 7 9.6 |

| M7×1 | 1d 1.5d 2d |

7 10.5 14 |

7.2 | 8.65-8.9 | 5.4 8.5 11.6 |

| M8×1 | 1d 1.5d 2d |

8 12 16 |

8.2 | 9.85-10.1 | 6.1 9.5 13 |

| M8×1.25 | 1d 1.5d 2d |

8 12 16 |

8.3 | 9.85-10.1 | 4.7 7.4 10.6 |

| M10×1 | 1d 1.5d 2d |

10 15 20 |

10.2 | 12.1-12.5 | 7.6 12 16.3 |

| M10×1.5 | 1d 1.5d 2d |

10 15 20 |

10.3 | 12.1-12.5 | 5 8 11.2 |

| M12×1.5 | 1d 1.5d 2d |

12 18 24 |

12.4 | 14.4-14.8 | 6.2 9.8 13.5 |

| M12×1.75 | 1d 1.5d 2d |

12 18 24 |

12.4 | 14.4-14.8 | 5.2 8.4 11.7 |

| M14×1.5 | 1d 1.5d 2d |

14 21 28 |

14.4 | 17.2-17.7 | 7 11.2 15.3 |

| M16×1.5 | 1d 1.5d 2d |

16 24 32 |

16.4 | 19.4-19.9 | 8.3 13 17.7 |

| M16×2 | 1d 1.5d 2d |

16 24 32 |

16.5 | 19.4-19.9 | 6.0 9.7 13.3 |

| M18×1.5 | 0.5d 1.0d 1.5d |

9 18 27 |

18.4 | 21.5-22 | 4.4 9.5 15 |

| M20×1.5 | 0.75d 1d 1.5d |

15 20 30 |

20.4 | 23.7-24.2 | 8 10.7 16.7 |

| M20×2.5 | 1d 1.5d 2d |

20 30 40 |

20.5 | 23.7-24.2 | 6.3 10 13.7 |

| M22×1.5 | 0.75d 1d 1.5d |

16.5 22 33 |

22.4 | 26.3-26.8 | 8.6 11.7 18 |

| M24×1.5 | 0.75d 1d 1.5d |

18 24 36 |

24.4 | 28.6-29.1 | 9.5 13 19.8 |

| M24×3 | 1d 1.5d 2d |

24 36 48 |

24.6 | 28.6-29.1 | 6.3 10 14 |

| M26×1.5 | 0.5d 0.75d 1d |

13 19.5 26 |

26.4 | 30.5-31 | 6.7 10.7 14.6 |

| M27×1.5 | 0.5d 0.75d 1d |

13.5 20.3 27 |

27.4 | 32.2-32.7 | 6.7 10.7 14.6 |

| M27×2 | 0.5d 0.75d 1d |

13.5 20.3 27 |

27.5 | 32.2-32.7 | 6.7 10.7 14.6 |

| M30×1..5 | 0.5d 0.75d 1d |

15 22.5 30 |

30.4 | 35.2-35.7 | 7.8 12.2 16.5 |

| M30×3.5 | 1d 1.5d 2d |

30 45 60 |

30.7 | 35.2-35.7 | 7 11 14.9 |

| M33×1.5 | 0.5d 0.75d 1d |

16.6 24.5 33 |

33.4 | 38.3-38.8 | 9.1 13.7 18.3 |

| M39×2 | 0.5d 0.75d 1d |

19.5 29.25 39 |

39.5 | 45.1-45.6 | 7.9 12.2 16.6 |

| M60×4 | 0.5d 1d |

32 64 |

64.9 | 65-66 | 7.3 15.6 |

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.