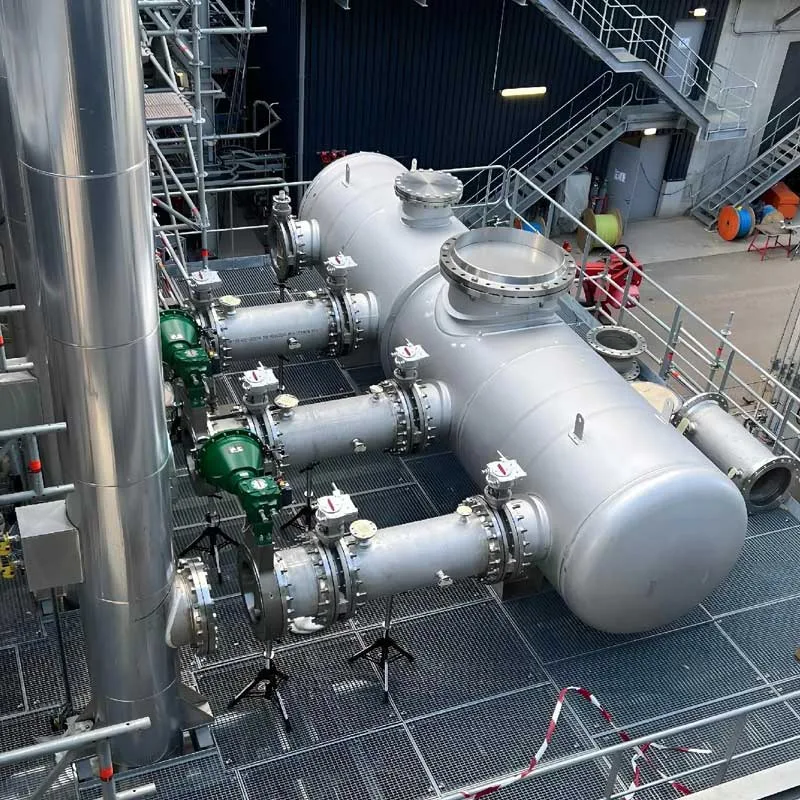

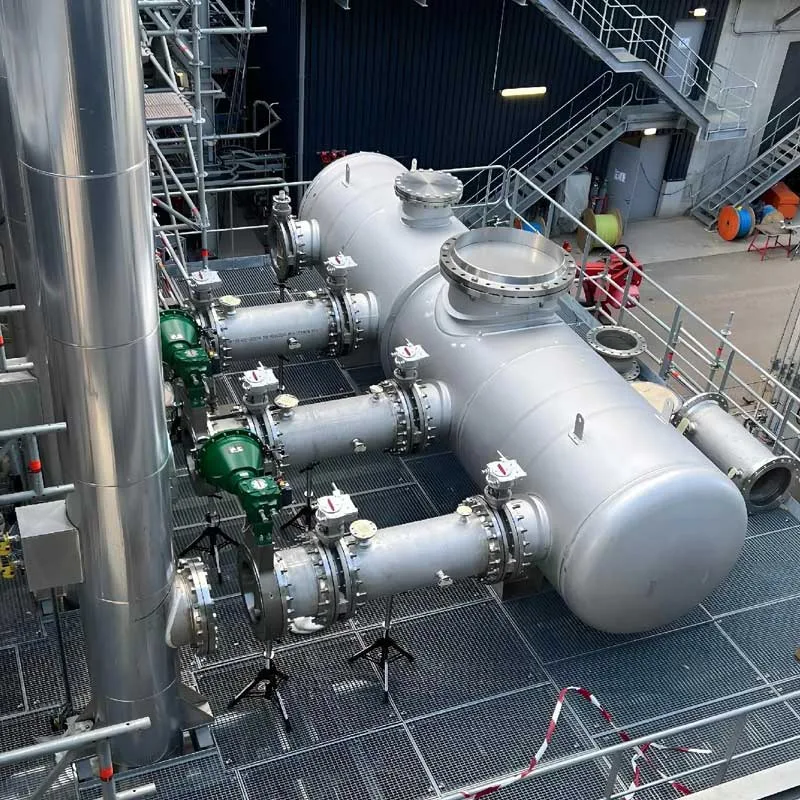

Pressure Vessel Product

A pressure vessel is a sealed container designed to hold gases or liquids at pressures substantially different from ambient pressure. They are critical components in industrial processes, engineered with strict safety standards to prevent catastrophic failure under high-pressure conditions.

Features:

Containment: Maintains structural integrity under internal/external pressure.

Safety-Critical: Designed and manufactured under stringent international codes (ASME BPVC Section VIII, PED, GB 150).

Customization: Configurations vary based on operational requirements.

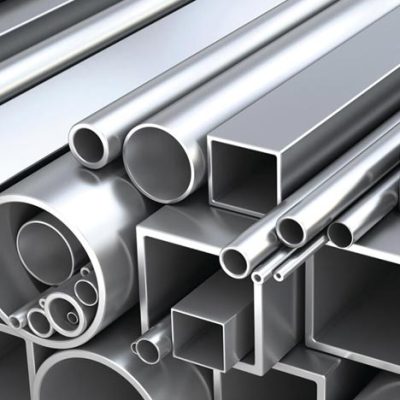

Main Components:

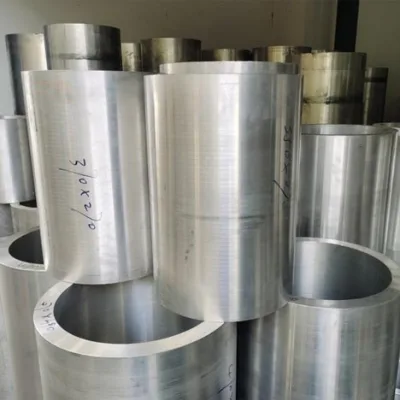

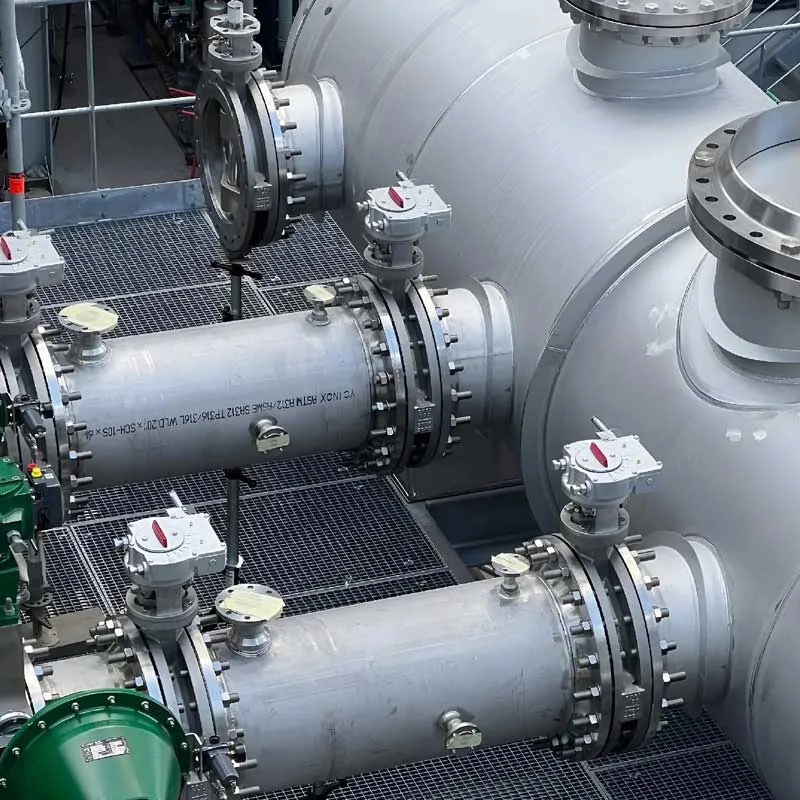

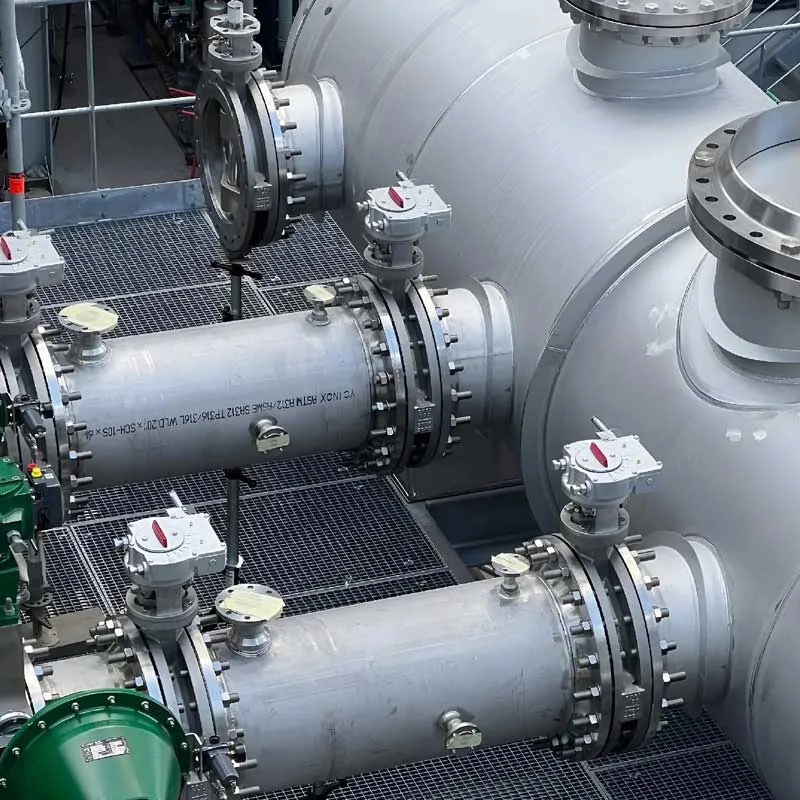

Shell: Cylinder and heads (elliptical, hemispherical, etc.)

Nozzles & Flanges: For fluid inlet/outlet and connections.

Supports: Saddles, legs, or skirts.

Safety Devices: Pressure relief valves, gauges, and monitoring systems.

Internals: Trays, coils, or catalysts (for process vessels).

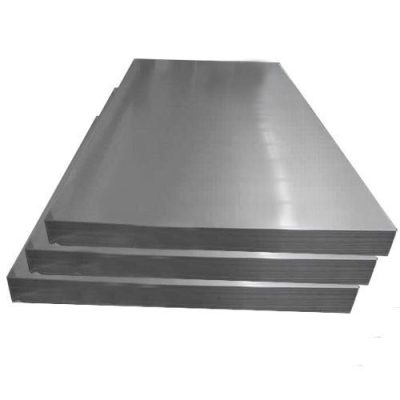

Material selection depends on pressure, temperature, fluid compatibility, and economic factors.

| Material Category | Common Grades | Key Properties & Typical Uses |

|---|---|---|

| Carbon Steels | SA-516 Gr.70, Q245R | Cost-effective; general service (air receivers, water tanks). |

| Low-Alloy Steels | SA-537, 16MnDR, Q345R | Higher strength and/or low-temperature toughness (ammonia vessels, cryogenic storage). |

| Stainless Steels | 304/304L, 316/316L, Duplex 2205 | Excellent corrosion resistance; food/pharmaceutical/chemical service. |

| Nickel Alloys | Inconel 625, Hastelloy C-276 | Extreme corrosion/oxidation resistance (highly acidic/alkaline environments). |

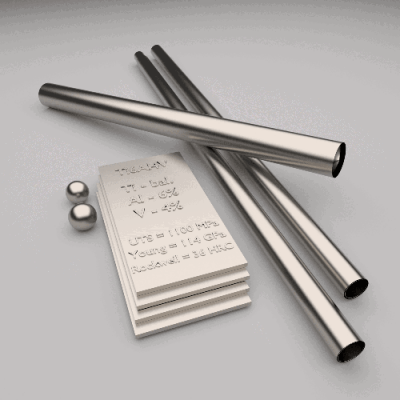

| Non-Ferrous Alloys | Aluminum 5083, Titanium Gr.2 | Lightweight or specialized corrosion resistance (e.g., seawater, chlorides). |

| Clad/Composite | SA-263 (SS-clad steel) | Combines strength of carbon steel with corrosion resistance of stainless layer. |

By Primary Function:

| Type | Description | Examples |

|---|---|---|

| Storage Vessels | Store fluids under pressure. | LPG tanks, spherical gas holders, compressed air receivers |

| Heat Exchangers | Transfer heat between fluids. | Shell-and-tube exchangers, condensers, evaporators |

| Process Vessels | Facilitate chemical/physical reactions. | Reactors, digesters, fermenters, autoclaves |

| Separation Vessels | Separate mixed phases/components. | Distillation columns, flash drums, scrubbers, filters |

By Geometry:

• Cylindrical: Most common; fabricated from rolled plate with welded heads.

• Spherical: Optimal stress distribution; ideal for large-volume storage (e.g., LNG tanks).

• Custom Shapes: Occasionally used for specific applications (e.g., dished ends).

Major Applications

Oil, Gas & Petrochemical:

Reactors, fractionators, separators, hydrocarbon storage.

Power Generation:

Boilers, steam drums, feedwater heaters (thermal plants).

Reactor pressure vessels (nuclear plants).

Hydrogen storage (emerging energy systems).

Chemical & Pharmaceutical:

Mixing, reaction, and sterilization vessels.

CIP/SIP systems; high-purity material handling.

Food & Beverage:

Fermenters, pasteurizers, pressure cookers (autoclaves).

Digesters, bleach towers, recovery boilers.

Aerospace & Defense:

Propellant tanks, hyperbaric chambers, test vessels.

Environmental & Renewable Energy:

Biogas holders, carbon capture columns, desalination units.

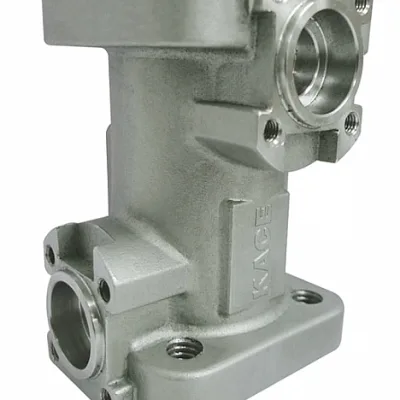

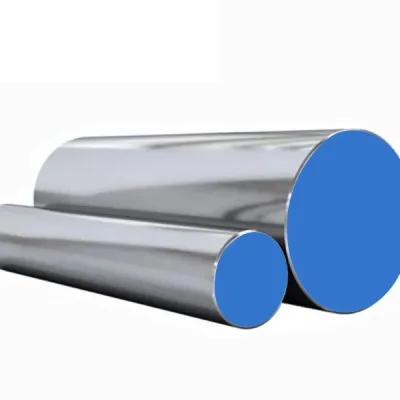

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.