Copper casting material

The principle of centrifugal casting: The method of centrifugal casting is to pour molten metal into a rotating mold. Due to the centrifugal force, the molten metal adheres tightly to the inside of the mold. As the mold rotates, the molten metal gradually solidifies into a tubular casting.

Our casting equipment includes high-frequency dissolution furnaces, large vertical centrifuges, horizontal centrifugal casting machines, stamping and forging machinery, sand treatment machines, and furan resin self hardening equipment。

The product features of centrifugal casting: Centrifugal casting products have finer microstructure and grain size, uniform composition distribution, good mechanical properties, and can reduce the generation of pores and sand holes. Copper castings made by centrifugal casting can be widely used in fields such as mechanical parts and ship parts.

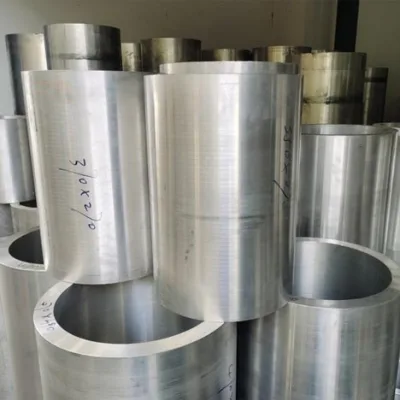

Sizes that can be produced by centrifugal casting

Outer diameter: 70-2000 mm

Length: The longest can reach 2500 mm

We can meet your customized needs and produce in both large and small quantities!

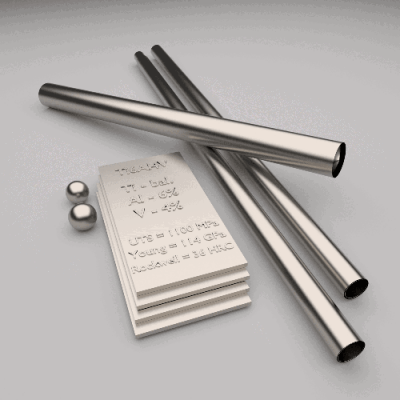

Metal materials that can be produced by centrifugal casting:

copper alloy: JIS BC、PBC、ALBC、ALBC3、TM3///ASTM C83600、C90700、C95800、C96200、C93700 /// Gunmetal, phosphor bronze, aluminum bronze, lead bronze, high tensile brass, any copper alloy material can be centrifugally cast.

stainless steel: SUS304、304L、316、316L、420、420、CF8、CF8A、CF8M、CF3MN, Any stainless steel or heat-resistant steel series can be centrifugally cast.

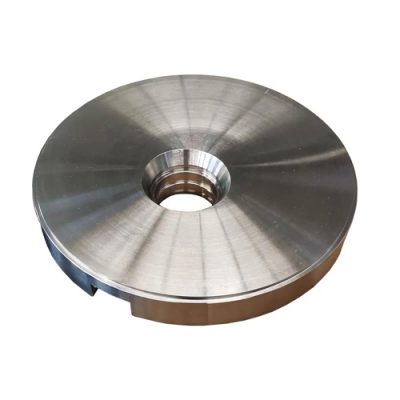

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.