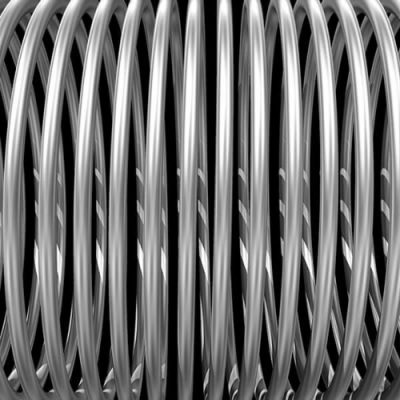

TA2-TC4 titanium alloy wire

Name:Titanium wire, TA2 titanium wire, TC titanium alloy wire

Specification:0.1-8.0mm

A, titanium wire specifications: φ0.8-φ6.0mm

B, glasses titanium wire specifications: φ1.0-φ6.0mm special titanium wire

C. Specification of titanium wire: φ0.2-φ8.0mm special for hangers.

Allowable deviation: -0.125~-0.14

Standard: GB/T 3623-2007

American Standard:ASTM B863,ASTM F136

Material:TA0,TA1,TA2,TA3,TA7,TA9,TA10, TC4,Ti1533

American Standard:GR1,GR2,GR3,GR5

Delivery condition:Annealed condition(M) Hot working condition(R) Cold working condition(Y)(Annealed, super raw wave flaw detection)

Length:500-3000MM

Packing:Bubble wrap with carton or wooden case

Surface treatment:Pickled surface Bright surface

Surface quality: high precision, good finish, no oxidized color, no cracks, peeling, splintering, mottling and inclusions. Allowed to have a slight, not more than the permissible deviation of the diameter of the wire material local scratches, abrasions, spots and pits.

Surface finish: clean, dust free, better acid resistance life.

Physical properties: better elongation and strength properties, no deformation after cold bending, no cracks after flattening and flaring. Filaments with a diameter of 3mm or more should be free of shrinkage tail, air holes, delamination, cracks, metallic or non-metallic inclusions.

Tests: tensile strength test, low times test, hardness test, chemical composition test.

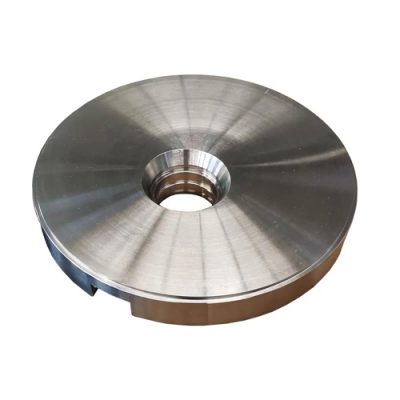

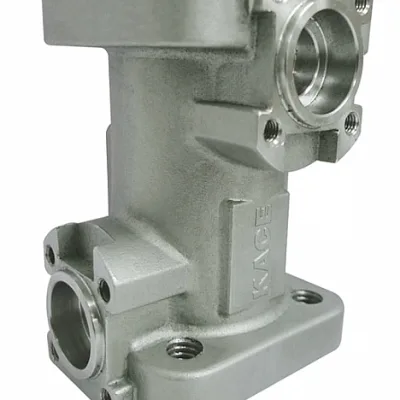

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.