Micro Stainless Steel Tubing

Micro Stainless Steel Tubing: Precision Engineering for Demanding Applications

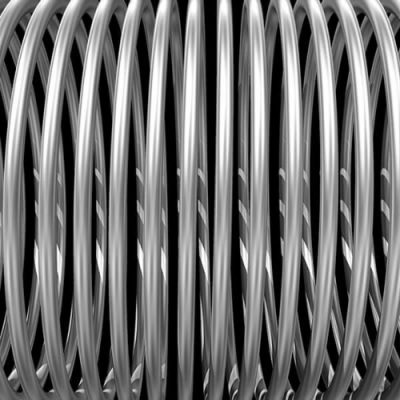

Micro stainless steel tubing refers to extremely small-diameter stainless steel tubes, typically with outer diameters ranging from 0.1 mm to 3.0 mm and wall thicknesses as thin as 0.02 mm. Manufactured primarily from austenitic grades such as 304 and 316 stainless steel, these tubes combine exceptional corrosion resistance, high strength-to-weight ratio, and biocompatibility—making them indispensable in industries where miniaturization, reliability, and cleanliness are non-negotiable.

The production of micro stainless steel tubing demands advanced manufacturing techniques, including cold drawing, precision rolling, and laser welding. Tight dimensional tolerances—often within ±0.005 mm—are achieved through multi-stage processing and rigorous in-line metrology. Surface finish is carefully controlled to minimize roughness, which is critical for fluid flow consistency and reduced particle generation, especially in medical and semiconductor applications.

Key application areas highlight its versatility. In medical devices, it serves as delivery channels for minimally invasive catheters, guidewires, and endoscopic tools—where kink resistance and sterilization stability are essential. In analytical instrumentation, such as HPLC and capillary electrophoresis systems, its inert surface prevents sample adsorption and ensures reproducible results. Aerospace and microfluidic sensor systems also rely on its thermal stability and leak-tight integrity under pressure and vacuum conditions.

Material selection further enhances functionality. For instance, 316L stainless steel is preferred in implantable or high-purity environments due to its low carbon content and superior resistance to chloride-induced pitting. Custom configurations—including coiled forms, flared ends, or laser-cut features—are increasingly available to support rapid prototyping and system integration.

As technology continues to shrink and performance expectations rise, micro stainless steel tubing remains a foundational enabler—bridging the gap between macro-scale engineering and micro-scale precision. Its ongoing development reflects broader trends toward smarter, smaller, and more resilient systems across healthcare, electronics, and advanced manufacturing.

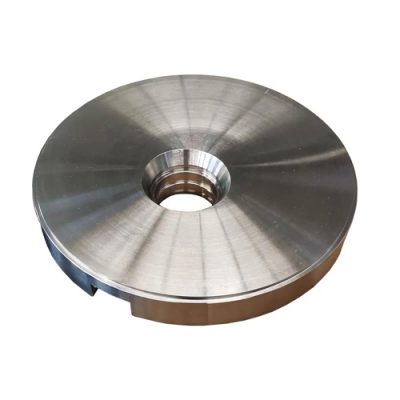

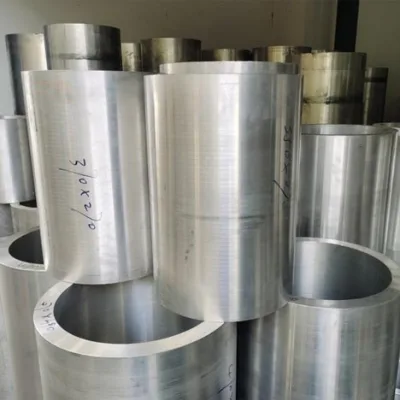

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.