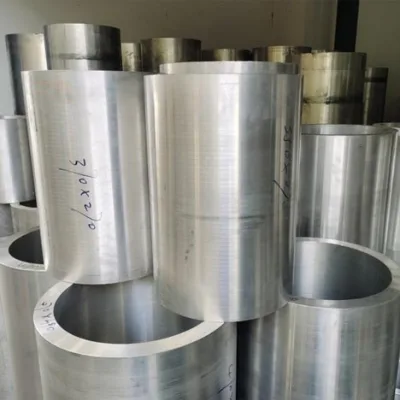

Internally polished honed pipe

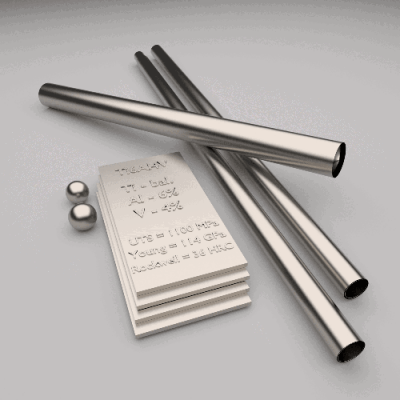

Internal polishing honing tube is a metal pipe that has undergone special processing, and its inner wall achieves a high surface finish through honing and polishing processes. Honing is a precision machining method that uses a honing head to rotate and reciprocate along the pipe wall, removing material micro roughness through the cutting action of abrasive particles.

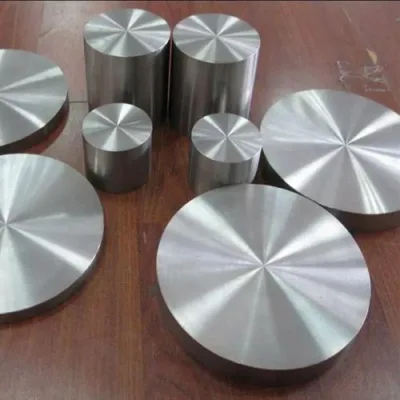

Polishing further reduces surface roughness on this basis, making the pipe wall smoother. These types of pipes are usually made of materials such as carbon steel, stainless steel, or alloy steel, depending on the requirements of the application environment.

Manufacturing process flow of internal polishing honing tube

The manufacturing process of internal polishing honing tube includes multiple key steps, and the following is a typical process:

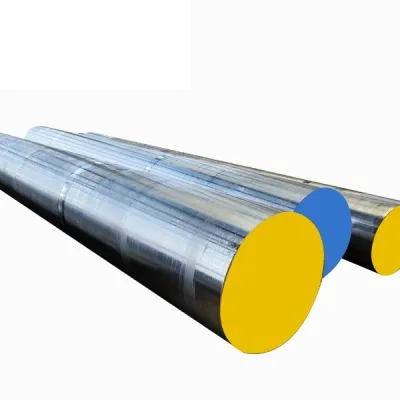

1. Raw material preparation: Select pipe blanks that meet the standards, conduct preliminary cleaning and inspection to ensure that there are no defects such as cracks or bubbles.

2. Rough machining: Form a basic tubular structure through cold drawing or hot rolling, and control the outer diameter and wall thickness dimensions.

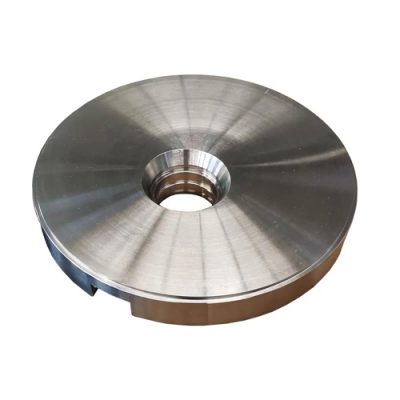

3. Honing treatment: Use honing equipment to process the inner wall of the pipe, gradually eliminating machining marks by adjusting the grinding stone particle size, pressure, and motion trajectory.

4. Polishing process: Mechanical or electrolytic polishing methods are used to further refine the surface structure until the target roughness level is achieved.

5. Cleaning and testing: Conveniently remove residual abrasives and metal shavings inside the pipe, and then measure the surface quality using optical instruments or stylus roughness meters.

6. Rust prevention treatment: Apply rust proof oil or coating as needed to avoid corrosion during storage and transportation.

7. Final inspection: Conduct excellent tests on the dimensional accuracy, surface smoothness, and mechanical properties of the pipes to ensure compliance with regulatory requirements.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.