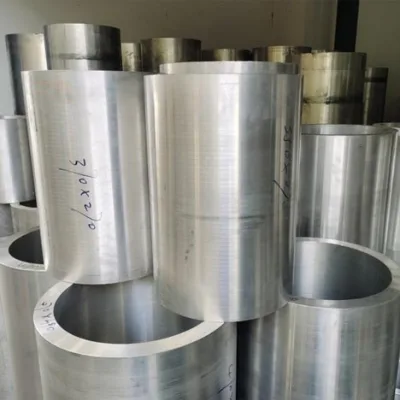

Flange Coupling Hub

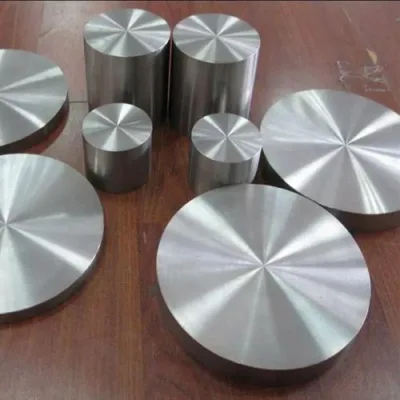

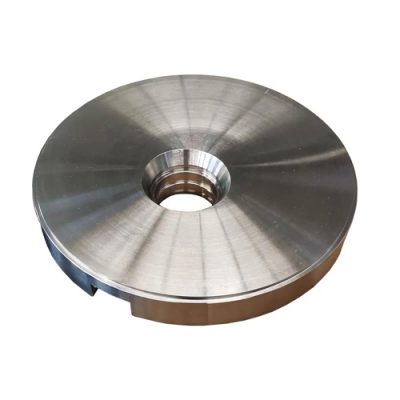

Flange coupling hub is a key component in modern mechanical power transmission systems. It can accurately and stably connect the rotating shaft, ensuring smooth torque transmission and a long service life. Our forged flange coupling hub combines high-strength metallurgical technology and CNC machining accuracy, providing stable and reliable performance even in harsh environments.

Common materials include:

42CrMo/AISI 4140 alloy steel, 40Cr / AISI 5140, Carbon steel (C45, Q235, Q345), 304 and 316 stainless steel for corrosion-resistant applications

According to performance requirements, heat treatment methods such as quenching and tempering, induction hardening, or nitriding can be used.

We can provide comprehensive customized services based on customer drawings, specifications, or performance requirements. The optional options include:

Hole types: cylindrical hole, tapered hole, keyway hole, keyway hole

Flange size and bolt circle diameter

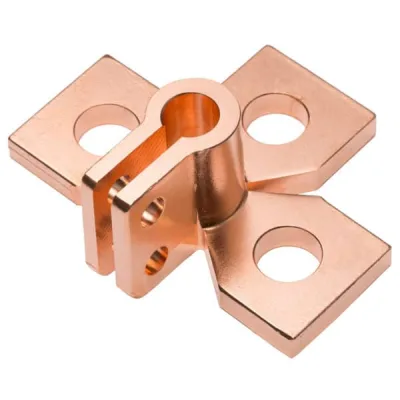

Surface treatment and coating

Hardness range of heat treatment

Material grade selection

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.