Gravity casting

Gravity casting is a metal casting process. Its core principle is to utilize Earth's gravity to inject molten metal from a gating system into a metal mold.

Unlike die casting, which requires high pressure to force metal into the mold, gravity casting relies entirely on the weight of the molten metal itself to fill the mold cavity. This makes the production process relatively smooth, resulting in a denser internal structure in the product.

Main characteristics of gravity casting

Good surface finish: Due to the smooth inner wall of the metal mold.

Excellent mechanical properties: Due to the rapid cooling rate of the metal mold, the casting has finer grains, a denser structure, and higher strength and hardness.

High dimensional accuracy.

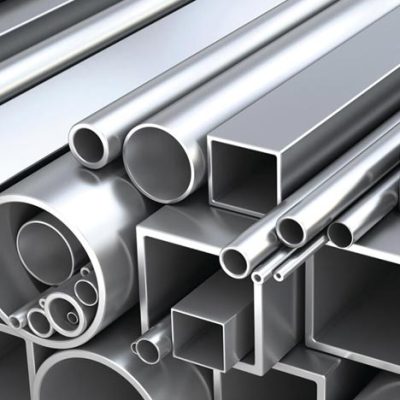

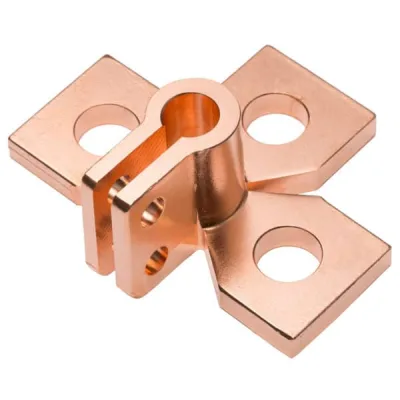

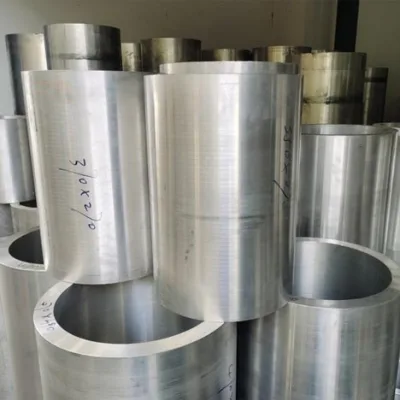

Applicable materials: Primarily used for non-ferrous metals such as aluminum alloys, magnesium alloys, and copper alloys.

Main application areas

Parts produced by gravity casting are widely used in various industries, especially in areas requiring strength, sealing, and surface quality:

Automotive industry: Engine cylinder heads, pistons, wheel rims, brake calipers, gearbox housings.

Motorcycles: Engine crankcases, cylinder heads.

Electronics and communications: Radiators, housings.

Home appliances: compressor housings, washing machine counterweights.

Aerospace: various high-requirement aluminum alloy structural components.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.