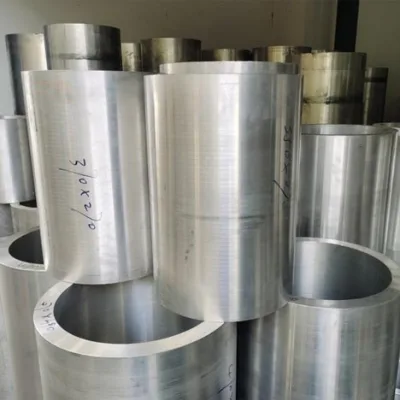

Thick walled pipe factory

In the vast system of modern industry, thick walled pipes play an indispensable role as a fundamental and critical metal material. It is not only the "skeleton" and "blood vessel" of many industries such as petroleum, chemical, power, and machinery manufacturing, but also the core component that carries pressure, transports media, and constructs frameworks.

Characteristics of thick walled pipes

*High strength and pressure resistance: Due to its significant wall thickness, thick walled pipes can withstand extremely high internal or external pressures without deformation or rupture, which is the primary condition for their application in high-pressure environments.

*Good structural stability: The thick pipe wall provides users with satisfactory resistance to bending and twisting, making it a reliable choice in large building structures and heavy machinery supports.

*Enhanced corrosion resistance and wear resistance: Thicker wall thickness means longer corrosion and wear allowance, and longer service life in harsh working conditions such as conveying abrasive media or in corrosive environments.

The main application areas of thick walled pipes are:

*Energy industry: drilling, extraction, and transportation pipelines for oil and natural gas, especially high-pressure oil and gas well pipelines and gathering pipelines; Boiler pipelines and high-pressure steam pipelines of thermal power plants; Certain structural components of nuclear power facilities.

*Heavy machinery and equipment: hydraulic supports and large bearing sleeves for construction machinery such as excavators and cranes; Roller conveyor and cooling wall of metallurgical equipment; Drive shaft sleeve for heavy-duty vehicles.

*Chemical and pressure vessels: The main pipelines and shell materials for high-pressure reactors, heat exchangers, and towers in fertilizer, chemical fiber, petrochemical and other enterprises.

*Infrastructure construction: Pier support columns for large bridges, key structural components for offshore platforms, giant columns for super high-rise buildings, etc.

*Other fields: shipbuilding, certain aerospace components, mold industry, etc.

Production process of thick walled pipes

The manufacturing of thick walled pipes is a complex process that integrates metallurgy, materials science, and precision machining technology. The core production processes mainly include the following:

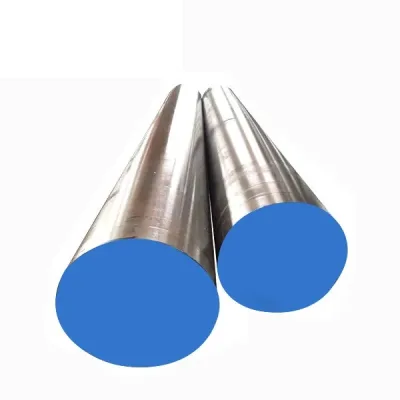

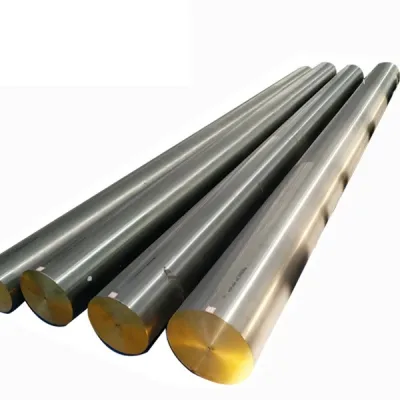

1. Hot rolling (expansion) process:

This is the mainstream method for producing large-diameter and thick walled pipes. Heating solid billets (steel ingots or continuous casting round billets) to high temperatures, piercing them through a perforating machine to form capillaries, and then using hot rolling machines (such as continuous rolling mills, periodic rolling mills) or hot expansion machines for longitudinal rolling or diameter expansion, ultimately rolling them into thick walled tubes of the desired size. Hot rolled pipes have the advantages of high production efficiency, wide range of production specifications (especially large diameter pipes), and good metal density.

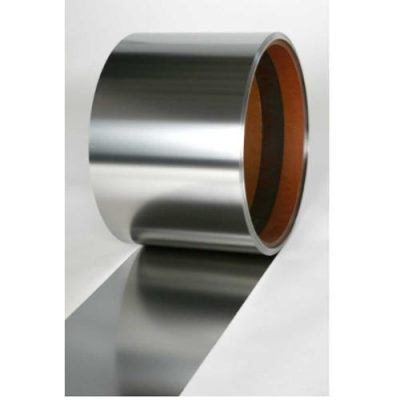

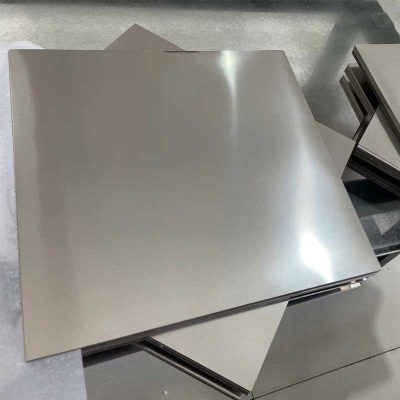

2. Cold drawing (rolling) process:

Usually used for producing small and medium-sized thick walled pipes with high dimensional accuracy, good surface smoothness, and better mechanical properties. Hot rolled tubes or semi-finished tubes are subjected to drawing or multi pass cold rolling through molds at room temperature to reduce the thickness and diameter of the tube wall and achieve the target size. Cold processing can significantly improve the strength and dimensional accuracy of steel pipes, but the production cycle is long and the cost is relatively high.

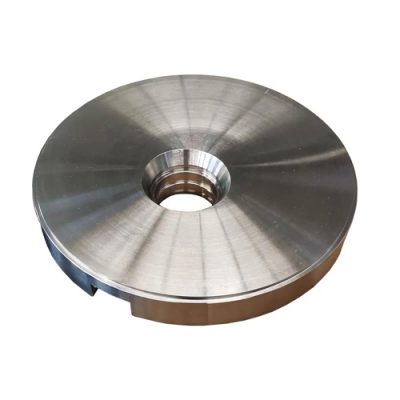

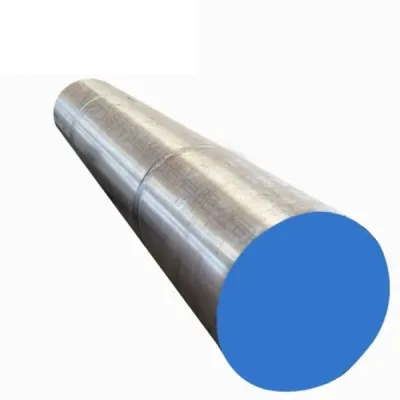

3. Forging process:

For thick walled pipes or fittings with special requirements such as extremely high pressure, complex shapes, and special alloys, forging is used. Using forging machinery to apply pressure to metal billets, causing them to undergo plastic deformation to obtain the desired shape and properties.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.