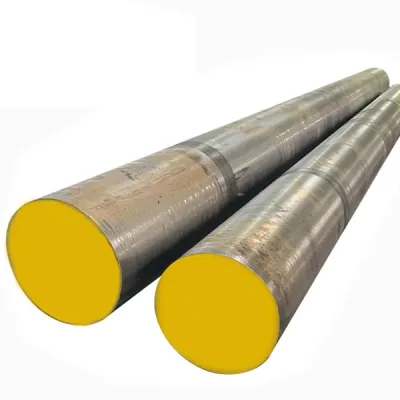

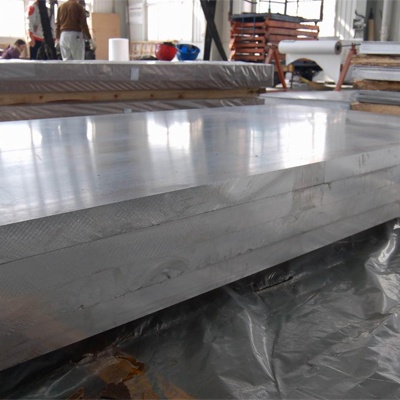

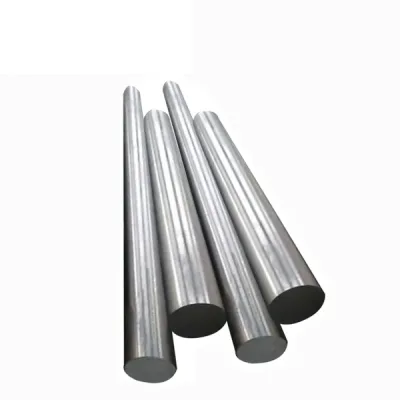

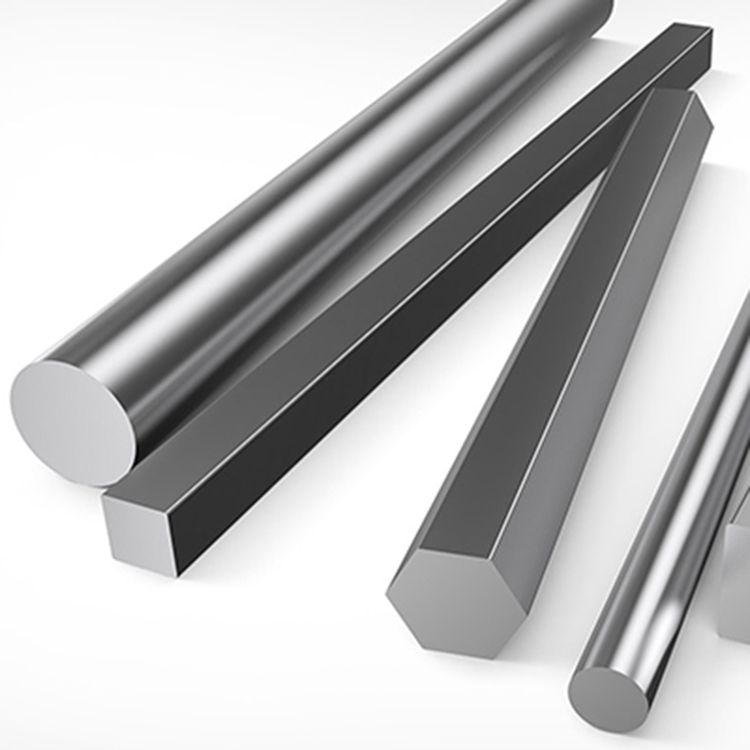

Aluminum copper alloy 2618 rod

Aluminum copper alloy 2618 rod is a heat treated strengthened aluminum alloy widely favored in the industrial field for its excellent heat resistance and mechanical properties. This alloy can maintain good strength and stability in high temperature environments, making it an ideal material choice for fields such as aerospace and automotive manufacturing.

Material Properties

Excellent high-temperature performance: capable of long-term operation at 150-200 ℃

Good machinability: excellent turning and milling performance

Moderate density: about 2.8g/cm ³

Excellent fatigue strength: particularly suitable for dynamic load components

Good welding performance: TIG and MIG welding can be used

This alloy is widely used in high-temperature components such as aviation engine pistons and cylinder heads. Used in the automotive industry for manufacturing turbocharger housings and high-performance engine components. In the mold industry, 2618 alloy is commonly used to manufacture working molds that require heat resistance. In addition, it is also used in the military industry to manufacture structural components with certain special requirements. After appropriate surface treatment, it can also be used for corrosion-resistant components in chemical equipment.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.