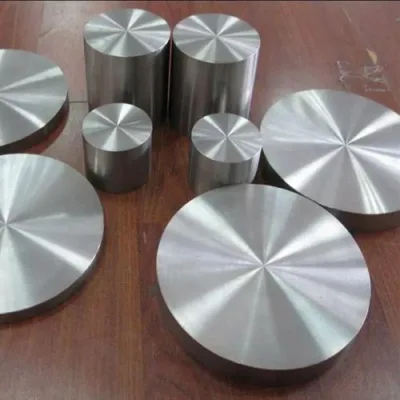

Advantages of circular forgings

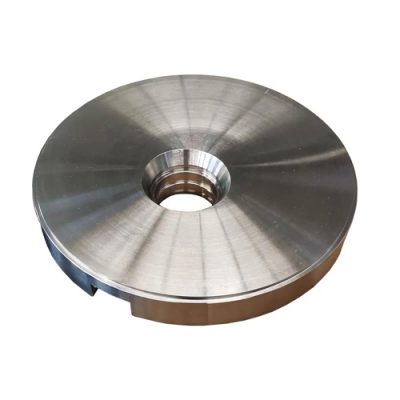

Ring forging not only endows mechanical parts with the required shape, but also optimizes the internal structure of the metal, enhances its mechanical and physical properties, exhibits excellent toughness, precision, raw material savings, good mechanical properties, and strength. The billet is pressure processed by forging machinery.

Ring forgings are widely used in fields such as shipbuilding, manufacturing, rail transportation, energy, and military industry by applying pressure to the billet through forging technology, which promotes plastic deformation of the material and improves its mechanical properties.

Ring forged products are popular for their excellent production efficiency, lightweight, outstanding mechanical properties, and ability to withstand strong impacts and heavy loads. These characteristics enable ring forgings to achieve the desired shape and mechanical properties through plastic deformation, and therefore are widely used in various fields such as power, steel, manufacturing, energy, and engineering machinery.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.