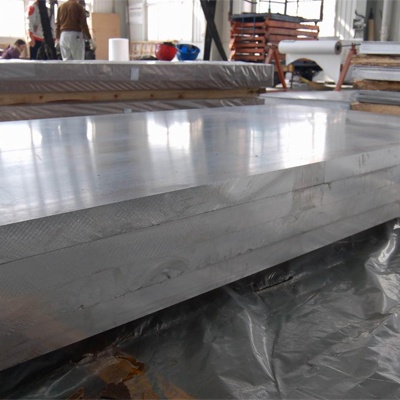

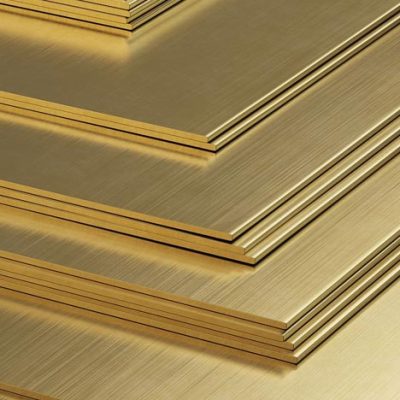

2014 Aluminum Alloy Plate

The 2014 aluminum alloy plate belongs to the aluminum copper magnesium silicon series of heat treatable strengthened aluminum alloys. It achieves high strength through solution treatment and aging treatment (usually T6 state), and its strength is second only to 7075 among common aluminum alloys.

Main features of 2014 aluminum alloy sheet:

High strength: Especially high tensile strength and yield strength.

Excellent machinability: Excellent cutting performance, good surface finish after processing.

Good heat resistance: can maintain a certain strength at higher temperatures.

Other Designations: ASTM B210, ASTM B211, ASTM B221, ASTM B241, ASTM B247, ASTM BB241, DIN 3.1255, MIL T-15089, QQ A-200/2, QQ A-225/4, QQ A-250/4, QQ A-367, SAE J454

Status: The most common is T6 status (artificial aging after solution heat treatment). Other states such as T3, T4, T651 (stress relieved T6 plate) are also applicable.

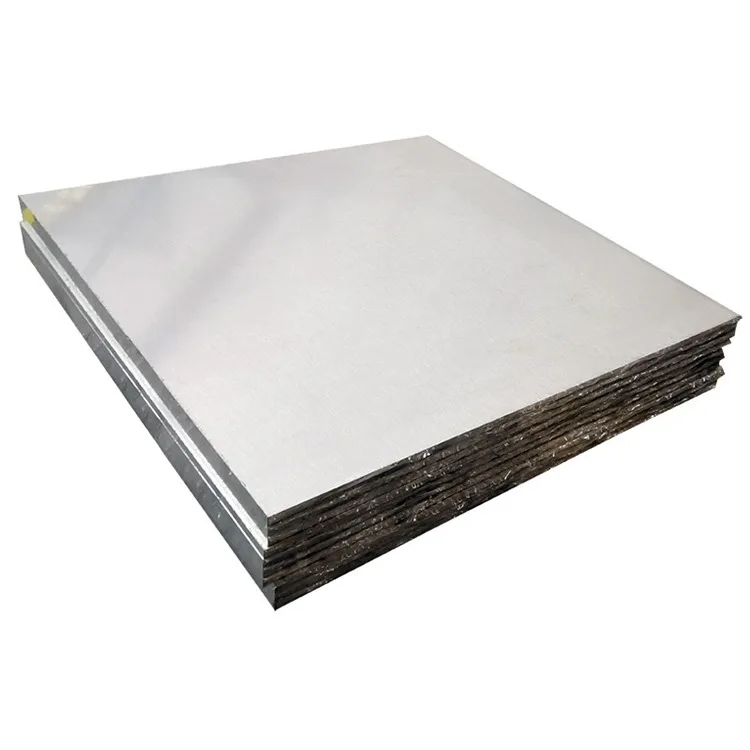

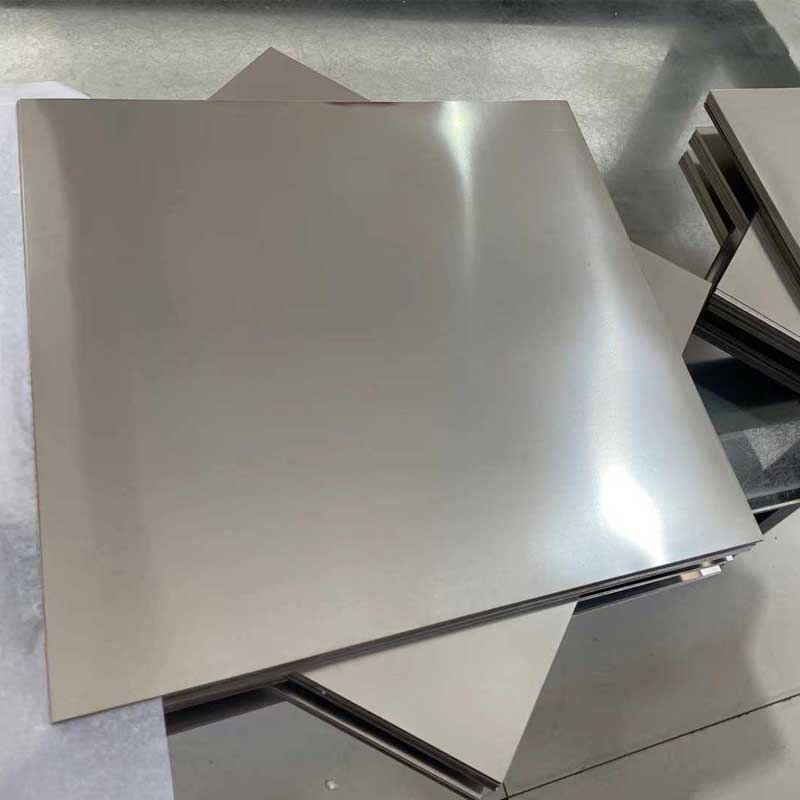

Thickness: typically ranging from 0.5mm to 240mm or even thicker.

Thin plate (<6mm) Medium thick plate (6mm-25mm) Thick plate (>25mm)

Width: The standard width is usually 1000mm, 1220mm, 1500mm, 2000mm, etc.

Length: Standard lengths such as 2000mm, 2440mm, 3000mm, 4000mm, etc., can also be customized.

Surface: It can provide matte surface (matte), glossy surface, brushed surface, etc., often with anodized pre-treatment film.

Equivalent Grades

| Standard | Grade | Region | Notes |

|---|---|---|---|

| AA | 2014 | USA | The American Aluminum Association designation commonly used in specifications |

| EN AW | 2014 | Europe | EN AW-2014 corresponds to AA2014 with similar composition and tempers |

| JIS | A2014 | Japan | Japanese designation A2014 aligns closely with AA2014 standards |

| GB/T | 2A14 | China | Chinese standard 2A14 approximates AA2014 chemical and mechanical limits |

Product Forms

| Form | Typical Thickness/Size | Strength Behavior | Common Tempers | Notes |

|---|---|---|---|---|

| Sheet | 0.5–240 mm | Rolling can produce strong, uniform properties | O, H14, T3, T6 | Thin-gauge sheet used where machining follows forming |

| Plate | 0.5–240 mm | Thick sections sensitive to quench rate and residual stresses | T6, T651 | Thick plate requires careful solution treatment and quench control |

| Extrusion | Cross-sections to several hundred mm² | Extrusion flow affects precipitate distribution | O, T5, T6 (after heat treatment) | Complex profiles possible but heat treating thicker extrusions is complex |

| Tube | OD up to a few hundred mm | Welding and seam quality important for pressure applications | O, T6 | Drawn or welded tubes; strength varies with wall thickness |

| Bar/Rod | Diameters 5–200 mm | Machinability and strength balance for fasteners/forgings | O, T6, T651 | Common for machined components and forged fittings |

Any size can be customized.

Temper Variants

| Temper | Strength Level | Elongation | Formability | Weldability | Notes |

|---|---|---|---|---|---|

| O | Low | High | Excellent | Excellent | Fully annealed; easiest to form and bond, lowest strength |

| H14 | Medium | Moderate | Good (limited) | Challenging | Strain-hardened; moderate strength via cold work |

| T5 | Medium-High | Moderate-Low | Fair | Poor-Moderate | Cooled from hot working and artificially aged; good dimensional stability |

| T6 | High | Low | Limited | Poor | Solution heat-treated and artificially aged; peak strength |

| T651 | High | Low | Limited | Poor | T6 with stress-relief by stretching; common for aerospace forgings |

Chemical Composition

| Element | % Range | Notes |

|---|---|---|

| Si | ≤ 0.5 | Minor impurity; low Si helps maintain toughness |

| Fe | ≤ 0.7 | Common impurity; excessive Fe can form intermetallics that reduce ductility |

| Mn | 0.4–1.2 | Refines grain structure and improves strength/toughness |

| Mg | 0.2–0.8 | Contributes to age-hardening in concert with Cu |

| Cu | 3.9–5.0 | Primary strengthening element (forms Al2Cu precipitates) |

| Zn | ≤ 0.25 | Minor; higher Zn not typical for 2xxx series |

| Cr | 0.1–0.4 | Controls recrystallization and grain growth during thermal processing |

| Ti | ≤ 0.15 | Grain refiner for cast and wrought products |

| Others | ≤ 0.15 (each) | Includes trace elements and residuals; Al balance |

Mechanical Properties

| Property | O/Annealed | Key Temper (T6/T651) | Notes |

|---|---|---|---|

| Tensile Strength (UTS) | 180–260 MPa | 420–480 MPa | UTS increases substantially on solution and aging |

| Yield Strength (0.2% offset) | 70–150 MPa | 340–410 MPa | Yield strength in T6 approaches mid/high hundreds MPa |

| Elongation (A%) | 20–30% | 4–10% | Ductility is traded off for strength in heat-treated tempers |

| Hardness (HB) | 40–70 HB | 120–150 HB | Hardness correlates with precipitate density and temper |

Physical Properties

| Property | Value | Notes |

|---|---|---|

| Density | 2.78 g/cm³ | Typical for Al-Cu wrought alloys |

| Melting Range | Solidus ~500–515°C; Liquidus ~635–645°C | Alloying shifts solidus downward compared with pure Al |

| Thermal Conductivity | ~120–150 W/m·K | Lower than pure Al due to alloying; depends on temper and grain state |

| Electrical Conductivity | ~30–40 % IACS | Reduced by copper and other solutes compared with pure Al |

| Specific Heat | ~880 J/kg·K (0.88 J/g·K) | Typical aluminum-range specific heat |

| Thermal Expansion | ~23.5–24.0 µm/m·K | Coefficient similar to other Al alloys; design for differential expansion needed |

Thanks to its high strength, high hardness, and excellent processing performance, 2014 aluminum plates are widely used in fields that require high weight and strength.

Aerospace field (most classic application):

Aircraft fuselage structural components, wing ribs, and bulkheads.

Spacecraft fuel storage tanks and structural frameworks.

Aircraft landing gear components (high load area).

Military and Defense Industry:

Armor plates (used for bulletproof flooring in light armored vehicles and helicopters).

Missile body, military vehicle structural components.

Transportation vehicles:

Truck body frame and bumper.

Suspension components and body structure of high-performance racing cars (such as F1).

Structural components of railway vehicles.

Molds and fixtures:

Plastic molds (due to their good machinability and strength).

Heavy duty fixtures and tooling used in aerospace or automotive manufacturing.

Other high stress structural components:

Bicycle frame (high-end, high-performance models).

High pressure gas cylinder.

Mechanical parts that require high strength and precision machining.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.