24 inch aluminum tube

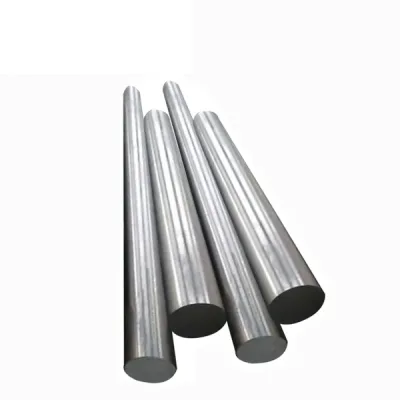

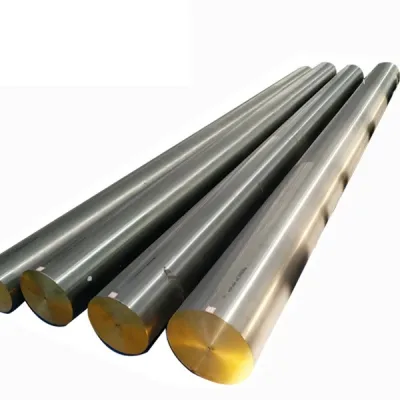

24 inch aluminum pipe is a kind of large-diameter industrial aluminum alloy pipe, which is widely used in energy, chemical, shipbuilding and large-scale structural engineering. With an outer diameter of 24 inches (approximately 609.6 millimeters), it has significant advantages such as lightweight, high strength, corrosion resistance, easy processing, and recyclability, making it an important choice to replace traditional carbon steel or stainless steel pipelines.

In terms of material grades, 24 inch aluminum tubes mainly use aluminum alloy series such as 5083, 6061, 6063, and 7075. 5083 aluminum tubes, due to their high magnesium content, have excellent corrosion resistance and welding performance in marine environments, and are commonly used in ship side pipelines and offshore platform structures; 6061 aluminum tube has good comprehensive mechanical properties and moderate strength after heat treatment, suitable for pressure vessels, bridge supports, and large mechanical frames; 6063 aluminum tubes have high surface smoothness and excellent extrusion formability, and are commonly used as supporting pipes for building curtain walls and decorative structural components; 7075 aluminum tube is an ultra high strength aerospace grade material. Although it has a high cost, it is also used in special equipment with strict requirements for load-bearing and weight reduction.

This type of product strictly follows authoritative standards both domestically and internationally. Internationally, ASTM B241 (General Aluminum Alloy Seamless Tube Standard) and ASTM B483 (Welded Aluminum Tube Standard) are mainly implemented; Domestically, clear regulations are made for dimensional tolerances, mechanical properties (such as tensile strength, yield strength, elongation), chemical composition, surface quality, and non-destructive testing based on GB/T 4436-2020 "Aluminum and Aluminum Alloy Tubes" and GB/T 6892-2015 "Aluminum and Aluminum Alloy Extruded Shapes for General Industrial Use". For specific purposes, relevant standards such as ASME BPVC Section II, EN 755, or JIS H4080 can be supplemented according to customer requirements.

The application scenarios of 24 inch aluminum tubes are highly compatible with their material characteristics. In the energy industry, it is used for low-temperature transmission pipelines in LNG receiving stations and cable protection sleeves inside wind turbine towers; In the field of transportation, as a large-span roof support column for high-speed railway station buildings and a load-bearing structure for heavy truck chassis; In municipal and environmental engineering, responsible for the ventilation and diversion pipes of large rainwater storage tanks and the process pipeline system of seawater desalination plants; In addition, it is increasingly playing a key role in aerospace ground support facilities and membrane structure tensioning systems for large sports venues. With the deepening of lightweight and green manufacturing concepts, 24 inch aluminum tubes are continuously expanding their high-end application boundaries with their low-carbon advantages throughout their entire lifecycle.

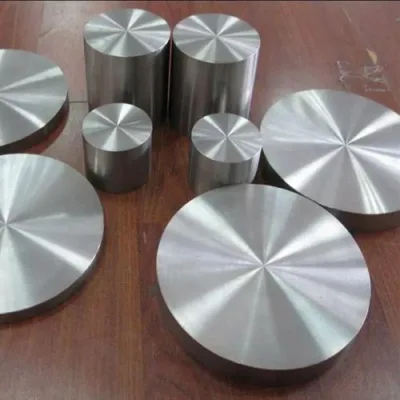

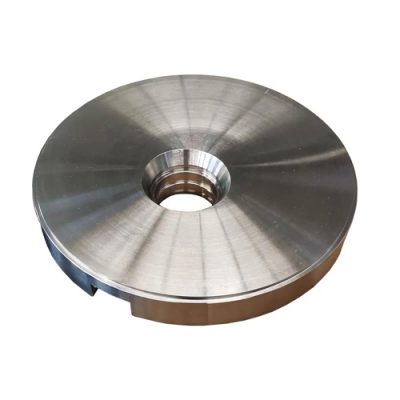

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.