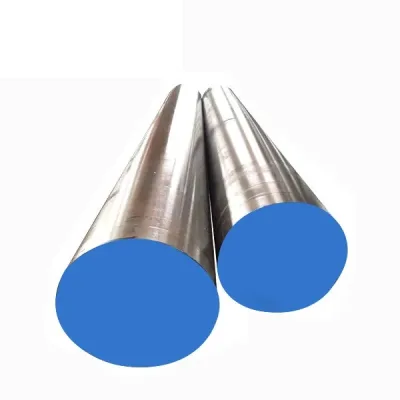

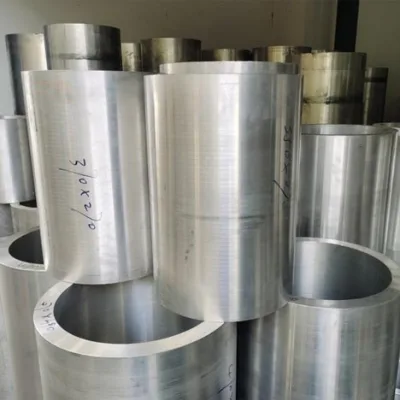

Cylinder forging

According to the movement mode of the billet, forging can be divided into free forging, upsetting, extrusion, die forging, closed die forging, and closed upsetting.

1. Free forging. There are two main methods for obtaining the desired forging: manual forging and mechanical forging, which use impact force or pressure to deform the metal between the upper and lower anvil blocks.

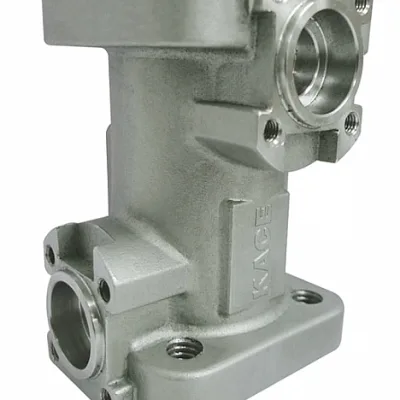

2. Die forging. Die forging can be divided into open die forging and closed die forging. Metal billets are deformed under pressure in a forging die chamber with a certain shape to obtain forgings, which can be further divided into cold heading, roll forging, radial forging, extrusion, and so on.

3. Due to the absence of burrs, the utilization rate of materials is high in closed die forging and closed forging. It is possible to complete the precision machining of complex forgings with one or several processes. Due to the absence of burrs, the stress area of the forging is reduced, and the required load is also reduced.

Forging Materials

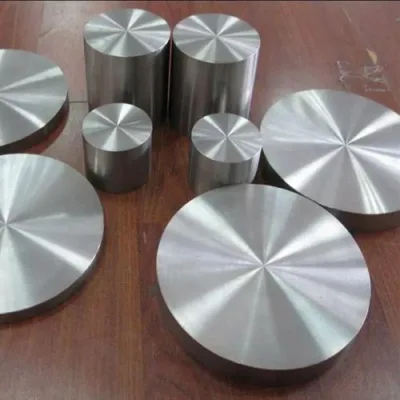

The forging materials mainly consist of carbon steel and alloy steel with various compositions, followed by aluminum, magnesium, copper, titanium and their alloys. The original states of materials include bar, ingot, metal powder, and liquid metal. The ratio of the cross-sectional area of a metal before deformation to the cross-sectional area after deformation is called the forging ratio.

Generally, circular or square bar materials are used as blanks for small and medium-sized forgings. The grain structure and mechanical properties of the bar material are uniform and good, with accurate shape and size, good surface quality, and easy to organize for mass production. As long as the heating temperature and deformation conditions are reasonably controlled, high-quality forgings can be forged without significant forging deformation.

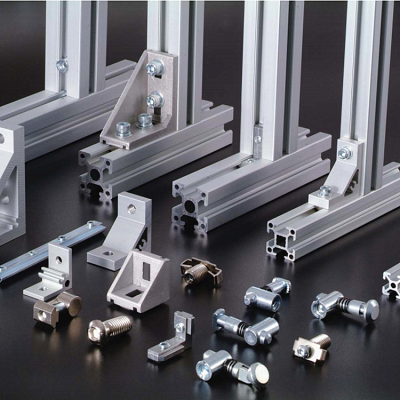

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.