Custom gear forgings

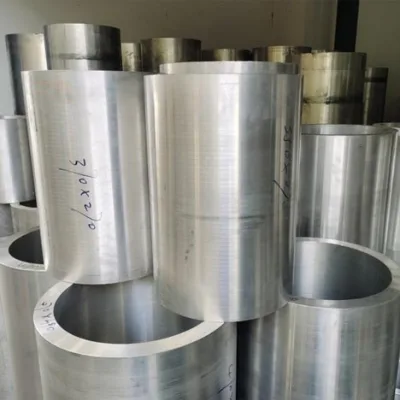

Gears, as core components of mechanical transmission systems, directly determine the stability, efficiency, and lifespan of equipment. Custom gear forgings, with their dual advantages of "on-demand customization + forging process," have become the preferred choice in the automotive, construction machinery, aerospace, and new energy industries, providing customized transmission solutions for various complex working conditions.

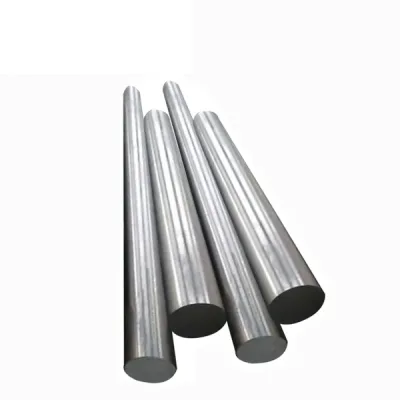

The core competitiveness of custom gear forgings stems from their "tailor-made" adaptability. Different equipment has varying requirements for gear module, number of teeth, tooth profile, precision grade, and load-bearing capacity, making standardized products insufficient for specific scenarios. From material selection (such as 40Cr, 20CrMnTi, gear steel, etc.) to structural design and forging process optimization, the entire process is customized to meet specific needs.

The forging process endows custom gear forgings with irreplaceable performance advantages. Compared to casting and machining, the forging process refines and densifies metal grains through high temperature and pressure, forming continuous metal flow lines, significantly improving the gear's strength, toughness, and wear resistance.

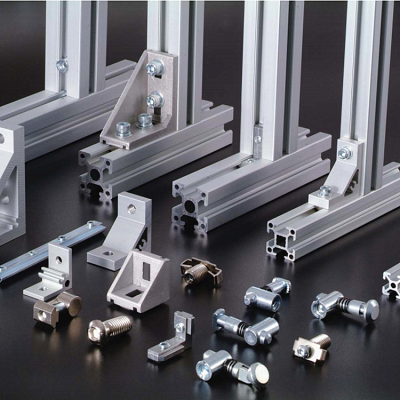

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.