High chromium bearing forgings

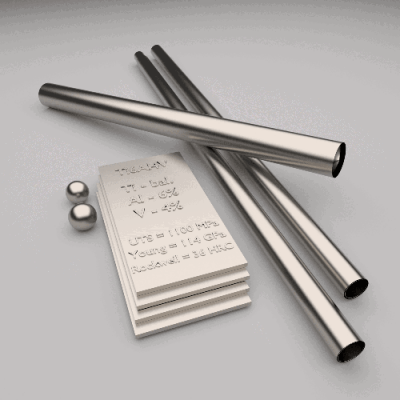

Forged high chromium bearing forgings optimize the internal structure of the metal through plastic deformation, significantly improving tensile strength, toughness, and fatigue resistance. They are suitable for the manufacturing of complex components in fields such as power and automotive, with high precision and long service life.

Processing high chromium bearing forgings through plastic deformation technology to shape components that conform to specific shapes and required mechanical properties.

Forging high chromium bearing forgings can not only produce the required mechanical shape, but also optimize their internal metal structure, significantly enhancing their mechanical and physical properties.

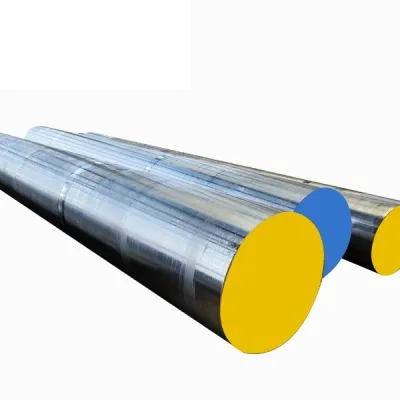

1. Solid forged parts: This type of forging is made from solid metal blocks and has a variety of shapes, ranging from simple geometries such as cylinders and cubes to complex structures.

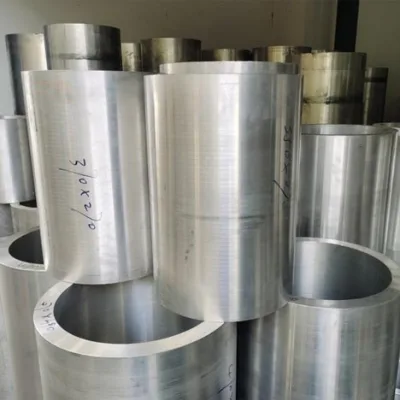

2. Hollow forgings: In contrast to solid forgings, this type of forging has a hollow structure inside, which is suitable for reducing weight or components that require internal channels, such as pipelines, ring components, etc.

3. Step shaped forgings: These forgings have unequal cross-sectional sizes and are commonly used to connect components of different sizes, such as shaft components.

4. Gear shaped forgings: These forgings have gear tooth shapes and are suitable for manufacturing transmission components such as gears.

5. Flange forgings: These forgings come with flange plates and are used for pipeline connections or as supporting structures.

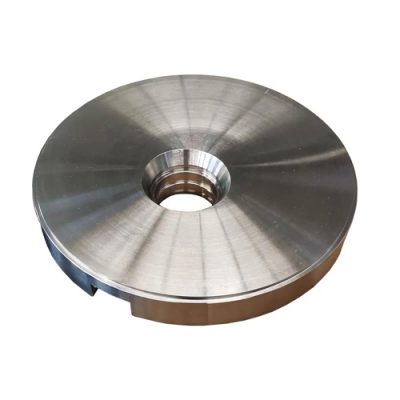

6. Forged impeller: used to manufacture impellers for rotating machinery such as turbines and pumps.

7. Forged crankshaft parts: These types of forgings are used in engines and other machinery, with complex shapes and multiple bends.

8. Forging parts of connecting rods: This type of forging is used to connect pistons and crankshafts, usually with complex shapes and diverse sizes.

9. Gear shaft forgings: These forgings combine the characteristics of gears and shafts, used to transmit torque and withstand bending loads.

10. Ring forged parts: This type of forging has a ring structure and is commonly used for bearing seats, seals, etc.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.