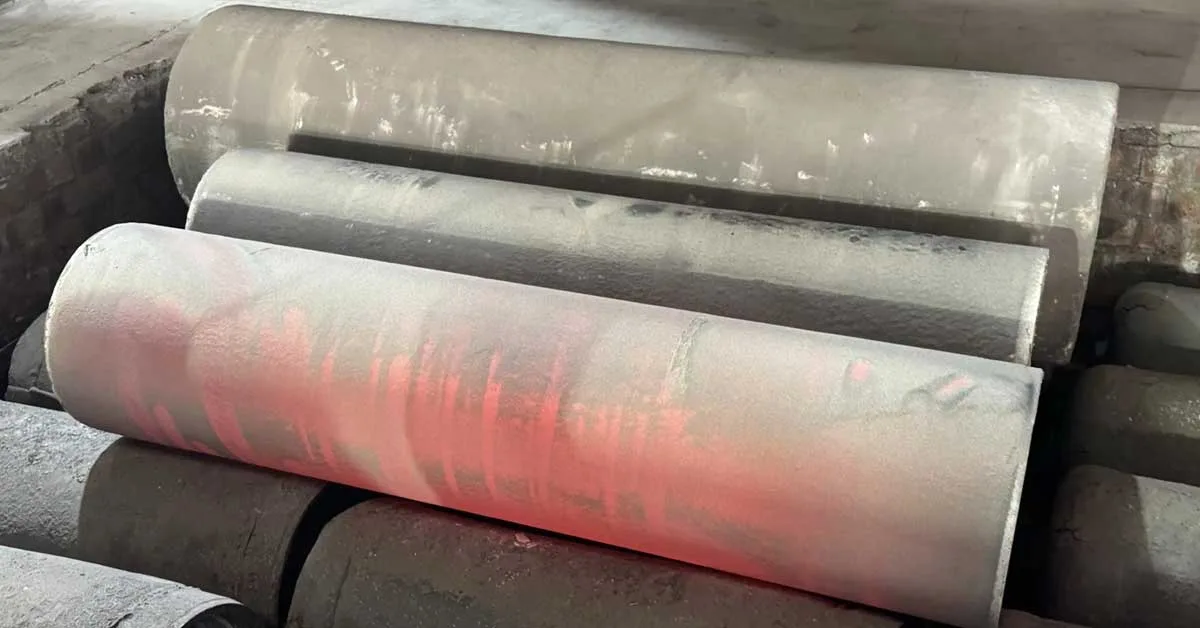

Centrifugal casting pipe

Centrifugal casting, a highly efficient special casting process, utilizes the centrifugal force generated by rotation to evenly distribute molten metal within the mold wall, thereby obtaining dense, high-performance tubular castings.

Non-ferrous metals: Primarily include copper alloys (such as tin bronze and aluminum bronze) and aluminum alloy centrifugal tubes. They possess excellent thermal and electrical conductivity and specific corrosion resistance, making them suitable for shipbuilding, power generation, and specialized machinery components.

Cast steel: Used for applications requiring higher strength and pressure resistance. Carbon steels such as ZG230-450, low-alloy steels such as ZG35CrMo, and high-alloy stainless steels such as ZG1Cr18Ni9 (type 304) are used. Stainless steel centrifugal tubes, with their superior resistance to acid and alkali corrosion, are the preferred choice for harsh environments such as chemical, petrochemical, and seawater treatment industries.

Sizes and Specifications

Centrifugal casting tubes offer an extremely wide range of sizes, fully demonstrating the flexibility of this process.

**Diameter:** Inner diameter can range from tens of millimeters (e.g., cylinder liners) to over 2000 millimeters (large water and sand conveying pipes).

**Length:** Typically 2-8 meters, depending on centrifuge capacity and process control. Some large horizontal centrifugal casting machines can produce extra-long pipes.

**Wall Thickness:** Ranges from several millimeters to hundreds of millimeters, precisely designed according to pressure resistance, wear resistance, and other requirements. The centrifugal process itself ensures uniformity and density in the wall thickness direction.

**Main Applications:**

**Machinery Manufacturing:** Small and medium diameter centrifugal cast pipes can be directly used as blanks for core moving parts such as cylinder liners, hydraulic cylinders, and rollers. Their fine-grained structure and excellent mechanical properties reduce subsequent processing.

**Petrochemical and Energy:** Alloy steel and stainless steel centrifugal tubes are used for oil and gas transportation, process piping in refining equipment, reactor linings, and coal powder and ash conveying pipelines in power plants, resistant to high temperatures, high pressures, and corrosive media.

**[Further details on applications would follow here]** Metallurgy and Mining: Centrifuge tubes made of high-chromium alloy cast iron and other materials are widely used as wear-resistant pipes in mine tailings, slurry transportation, and sintering dust removal pipelines in metallurgical plants, significantly extending their service life.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.