Specialized tubes for hydraulic cylinders

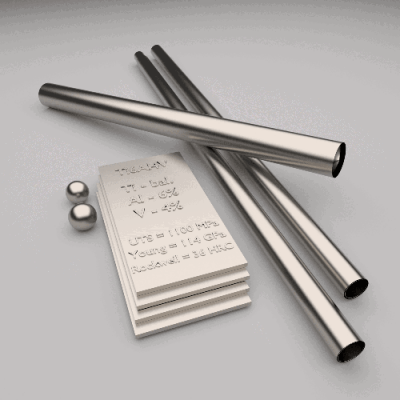

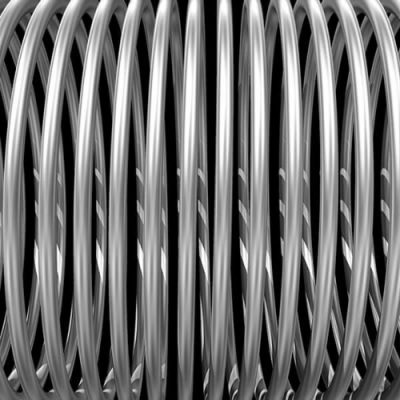

Precision Hydraulic Seamless Pipe / Seamless Steel Tube for Hydraulic Cylinders: Core Name, Emphasizing High Dimensional Accuracy and Surface Finish.

Cold drawing/rolling: A primary manufacturing process that ensures precise dimensions, smooth surface finish, and enhanced strength of the tubing.

Honing: A precision finishing process for the inner wall of cylinder bores, creating a crosshatched pattern to enhance oil retention and reduce seal wear. Honed tubes serve as the direct material for finished cylinder bores.

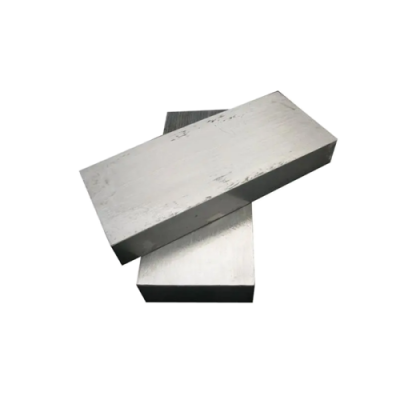

Tempering (quenching + tempering): For materials such as 45#, 27SiMn, and 42CrMo, tempering is a necessary process to achieve high strength and toughness. Manufacturers specializing in tempered pipes are more professional.

Internal hole roughness: Key indicator, typically requiring Ra ≤ 0.4μm, or even Ra 0.1-0.2μm.

Straightness: Affects the assembly and smooth operation of the hydraulic cylinder.

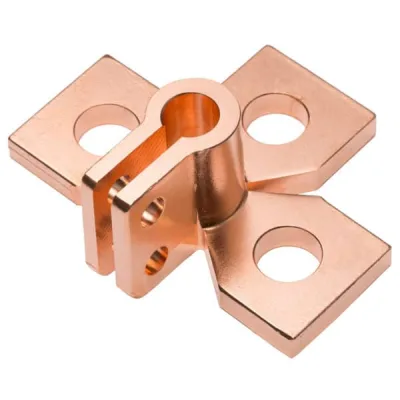

Chrome-plated rod/polished rod: Refers to piston rod material, typically made of 45# or 35# steel, with a hard chrome plating (20-50μm) and polishing, offering wear resistance and rust prevention.

DIN 2391 / EN 10305-1 / GB/T 3639: Commonly used technical standards for precision seamless steel pipes both domestically and internationally.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.