Medical Stainless Steel Tube

Medical Stainless Steel Tube: Precision Engineering for Healthcare Applications

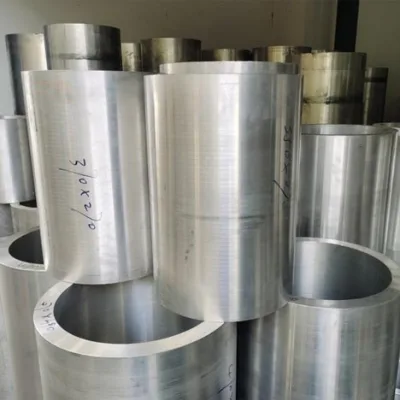

Medical stainless steel tubes are specialized hollow cylindrical components engineered to meet the stringent requirements of healthcare and biomedical applications. Unlike standard stainless steel tubing, these products undergo rigorous material selection, precision manufacturing, and comprehensive quality control to ensure biocompatibility, corrosion resistance, mechanical reliability, and sterilization compatibility.

The most commonly used grade is austenitic stainless steel 316L, which contains molybdenum to enhance resistance against chloride-induced pitting—a critical feature in physiological environments. Its low carbon content minimizes carbide precipitation during welding or heat treatment, preserving corrosion resistance and reducing the risk of metal ion leaching into bodily fluids. Additional grades such as 17-4 PH and nickel–titanium (Nitinol) alloys are also employed where high strength, shape memory, or superelasticity is required—particularly in cardiovascular stents, guidewires, and minimally invasive surgical devices.

Manufacturing processes emphasize dimensional accuracy and surface integrity. Cold drawing, electropolishing, and passivation are standard steps to achieve tight tolerances—often within ±0.02 mm for outer diameter—and ultra-smooth inner and outer surfaces with roughness values below 0.4 µm Ra. These attributes minimize thrombogenicity, facilitate catheter navigation through tortuous vasculature, and prevent bacterial adhesion. Cleanroom assembly and packaging under ISO 13485-certified conditions further ensure particulate-free, endotoxin-controlled delivery.

Regulatory compliance is integral to the lifecycle of medical stainless steel tubes. Manufacturers must adhere to international standards including ASTM F138 (for surgical implant stainless steel), ISO 5832-1, and FDA 21 CFR Part 820. Traceability—from raw material melt numbers to final inspection reports—is mandatory, supporting audit readiness and post-market surveillance. As medical device innovation advances toward smaller, smarter, and more integrated systems, the role of high-performance stainless steel tubing remains foundational—bridging engineering excellence with clinical safety and patient outcomes.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.