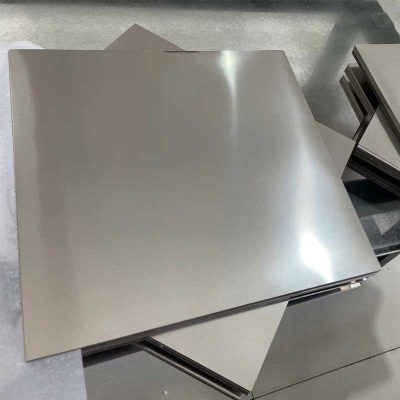

304 stainless steel ring forging

304 stainless steel ring forgings apply mechanical force to the metal billet through forging process, causing plastic deformation of the material and forming the desired shape and quality. This process not only eliminates the pores and defects inside the metal, but also significantly improves the mechanical properties of the product.

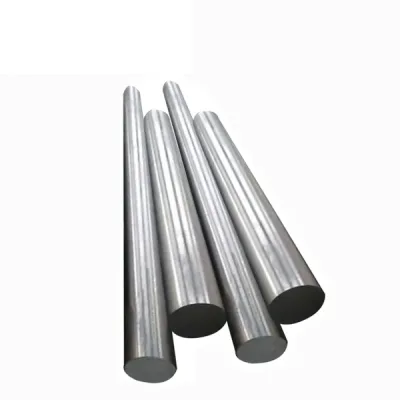

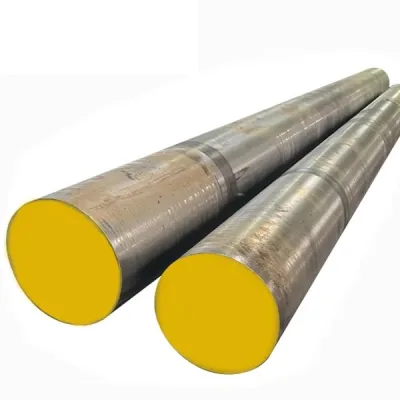

1. Solid forged products: These forgings are forged from solid metal blocks, and their shapes can be simple geometric shapes such as round bars, blocks, or more complex configurations.

2. Hollow forging products: Compared to solid forging products, hollow forging products have a hollow structure inside, which is suitable for reducing weight or components that require internal channels, such as pipes, ring components, etc.

3. Step shaped forged products: forged parts with different cross-sectional sizes, commonly used to connect components of different sizes, such as shaft components.

4. Gear shaped forged products: Forged parts with gear tooth characteristics, suitable for the manufacturing of transmission components such as gears.

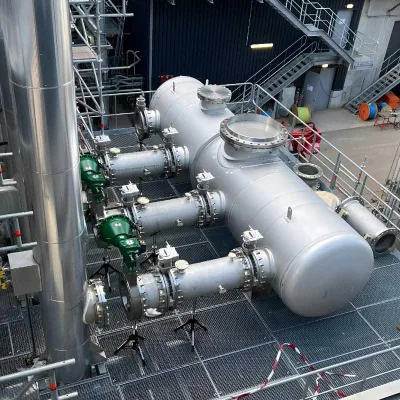

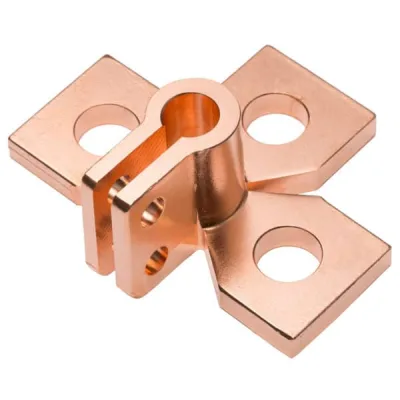

5. Flange shaped forged products: Forged parts with flanges, used for pipeline connections or as supporting structures.

6. Forged impeller products: suitable for manufacturing impellers of rotating machinery such as turbines and pumps.

7. Crankshaft shaped forged products: suitable for engines and other machinery, with complex shapes and multiple bends.

8. Connecting rod forging products: used to connect pistons and crankshafts, usually with complex shapes and sizes.

9. Gear shaft forging products: Forging parts that combine gears and shafts, used to transmit torque and withstand bending loads.

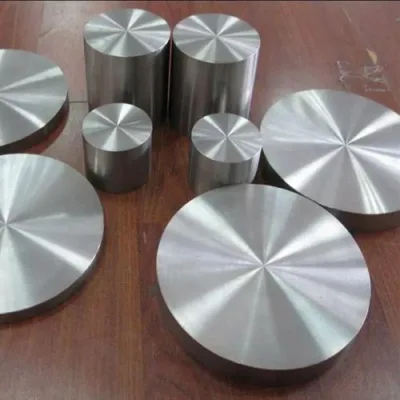

10. Circular forging products: Forged parts with circular structures, commonly used for bearing seats, seals, etc.

304 stainless steel ring forgings have been widely used in various fields such as ships, energy, engineering machinery, electricity, and rail transit. The forging process can not only produce the required mechanical shape parts, but also optimize the internal structure of the metal, significantly improving the mechanical and physical properties of this type of forging.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.