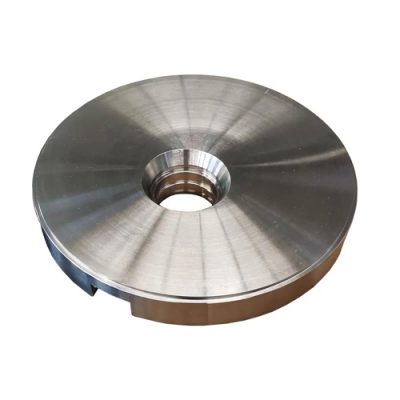

Introduction and customized application of 7075 T6 aluminum alloy forgings

7075 T6 aluminum alloy forgings are a type of high-performance lightweight structural material, widely used in high-end manufacturing fields with strict requirements for mechanical properties and reliability due to their excellent strength to weight ratio, excellent fatigue resistance, and good machinability. This material is mainly composed of zinc as the main alloying element, supplemented by strengthening components such as magnesium and copper. After solid solution treatment and artificial aging (T6 state), the tensile strength can reach over 570 MPa and the yield strength exceeds 500 MPa, while maintaining good fracture toughness. It is currently one of the most outstanding grades in commercial aluminum alloys in terms of comprehensive mechanical properties.

In practical applications, 7075 T6 aluminum alloy forgings are commonly used in aerospace structural components, such as aircraft landing gear brackets, wing joints, engine mounts, and other key load-bearing components; It is also widely used in high-performance racing chassis components, drone body frames, precision optical instrument brackets, and high-end sports equipment such as mountain bike suspension forks and climbing equipment connectors. Its excellent dynamic load response capability and dimensional stability make it exhibit significant advantages in working conditions with frequent vibration, complex temperature changes, or long-term service requirements.

We provide customized services throughout the entire process to meet the differentiated needs of customers in different industries. From initial drawing analysis, material heat treatment process matching, 3D forging die design, to small-scale trial production verification and large-scale stable delivery, all can be executed accurately according to customer technical specifications. Supports multiple surface treatment options, including anodizing, hard anodizing, chemical conversion coatings, and special coatings, to enhance corrosion resistance and wear resistance. At the same time, we can cooperate with customers to complete material certification (such as AMS, EN, GB standards), non-destructive testing (UT/RT/MT), and comprehensive mechanical performance testing reports, ensuring that each customized component meets strict quality and compliance requirements.

As a professional manufacturer of high value-added aluminum alloy structural components, we continuously optimize the forging process control and heat treatment parameter window to ensure uniform microstructure, reasonable streamline, and low residual stress of 7075 T6 forgings. In the future, we will further expand our deep customization capabilities in emerging fields such as new energy equipment, intelligent robot joint modules, and lightweight rail transit components, to help customers achieve higher levels of lightweight and system integration innovation.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.