Manufacturing Hydraulic Cylinder Sleeves

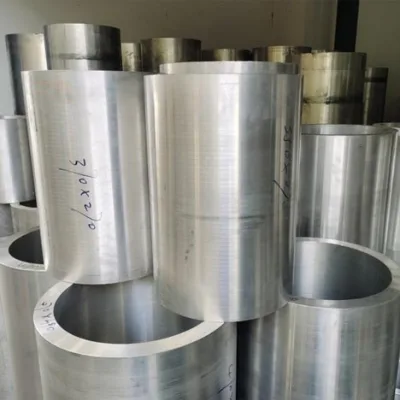

We receive a forging made of A35 steel as a blank.

The sleeve manufacturing process:

➯ Conduct incoming inspection.

➯ Develop a technical roadmap.

➯ Place the workpiece on a jig boring machine, trim the workpiece, and bore a centering hole for the tool.

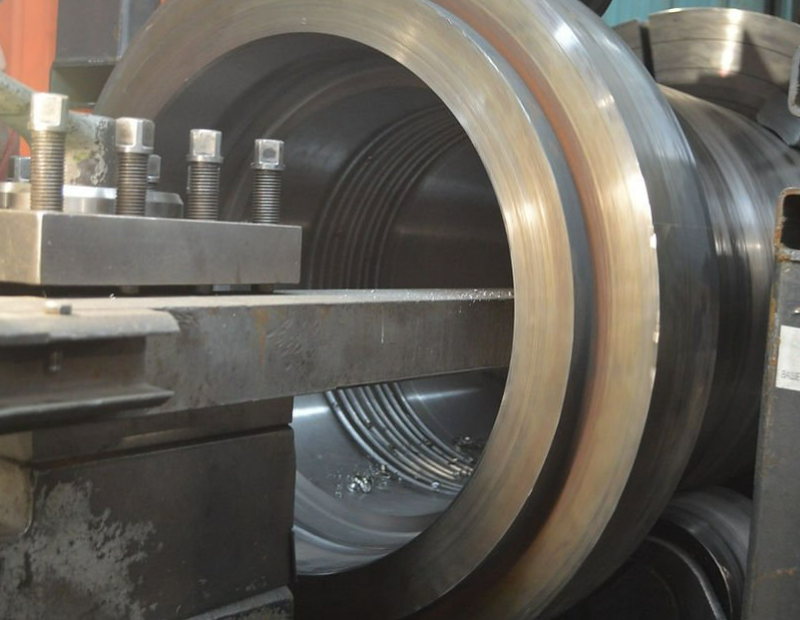

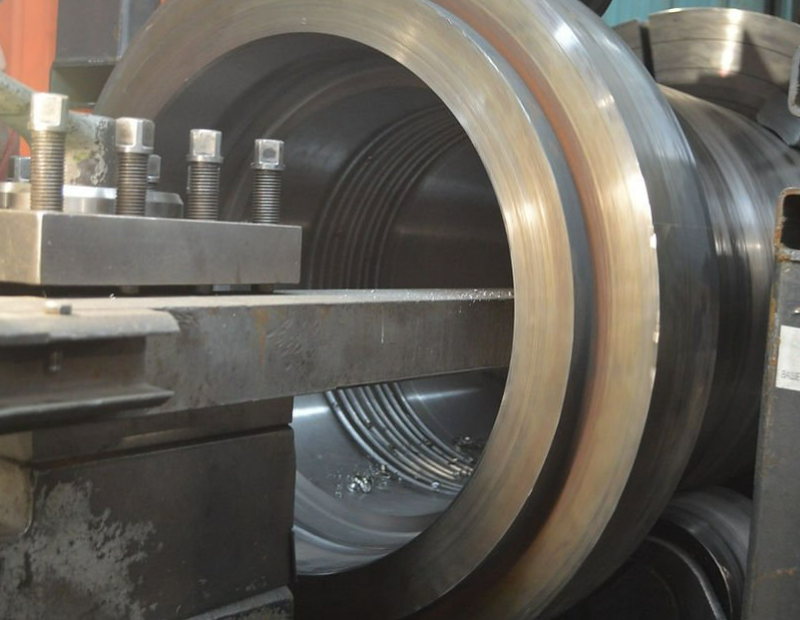

We manufacture equipment mounted on a lathe and machine the forging according to the customer's drawings.

Grind the inner diameter of the sleeve.

Machine the groove for the support ring.

Drill the hole for the thread using mobile milling equipment.

Cut the thread into the end mounting hole.

The final stage is factory inspection—the hydraulic cylinder sleeve is manufactured according to the drawings.

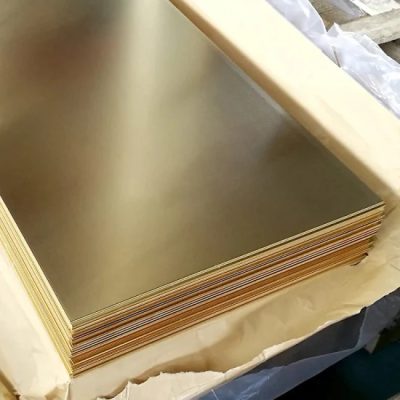

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.