Precision spline shaft forging

Spline shaft forgings are precision components used to transmit torque and coordinate the motion between mechanical components. Its grooves or teeth precisely match with the hub or gear, forming a stable and efficient connection. Each spline shaft is formed using closed die forging technology, followed by CNC machining and heat treatment to refine the grain structure and improve strength. These shafts perform reliably in applications that require high precision and durability, such as transmissions, hydraulic systems, and heavy machinery.

Manufacturing process

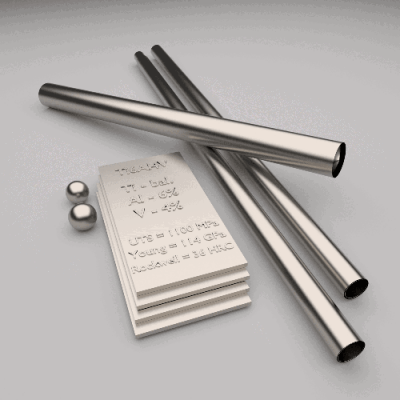

Material selection - Choose alloy steel and carbon steel, such as 42CrMo, 4140, and 20CrMnTi, to achieve good fatigue strength and impact strength.

Closed die forging - forging the heated billet in a precision mold to form a dense and continuous grain flow.

Heat treatment - quenching and tempering can improve hardness, wear resistance, and toughness.

CNC machining - splines, keyways, and threads are machined with strict tolerances to ensure reliable fit in spline shaft couplings or transmission systems.

Inspection and Testing - Each spline shaft forging undergoes UT, MPI, and dimensional inspection in accordance with ISO 9001:2015 standard.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.