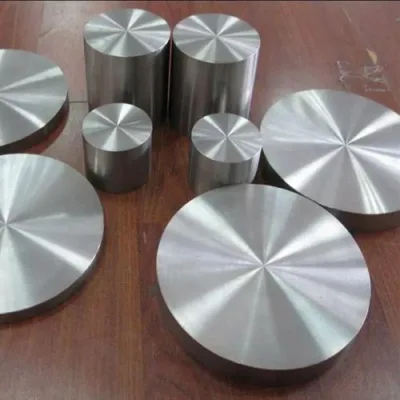

CNC Machining Parts Precision forged steel ring

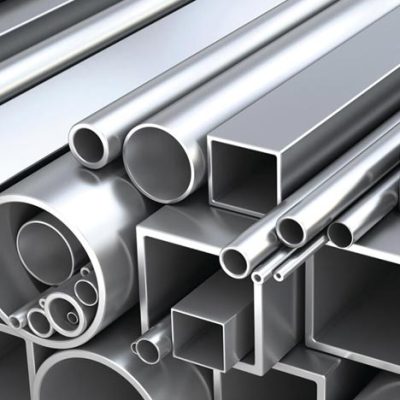

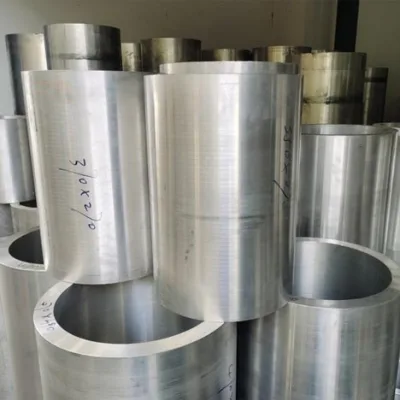

We supply forged steel rings for bearing, rotating, and sealing interfaces. Our ring forgings combine hot rolling, open die forging, and precision CNC machining processes to ensure uniform microstructure and stable geometric shape. For gear applications, the ring blank is machined according to AGMA/ISO gear tolerances and the required allowances for hobbing or grinding.

Steel ring forging process

We produce forged steel rings through precise and step-by-step controlled hot forging processes to ensure structural integrity and uniform grain flow.

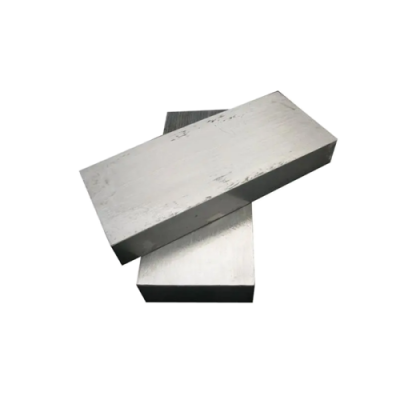

Material Preparation - Select certified alloys or carbon steel billets (such as 42CrMo4, 4140, 20CrMnTiH) to ensure mechanical reliability.

Heating - uniformly heat the steel billet to 1050-1250 ° C to achieve optimal plasticity and deformation control.

Punching and pre forming - Punching and pre forming steel billets to adjust grain direction and achieve uniform metal distribution.

Ring rolling - enlarging the diameter on a radial axial ring rolling mill to ensure roundness, density, and fine microstructure.

Heat treatment - carry out normalizing, quenching, and tempering treatments to improve hardness, strength, and impact resistance.

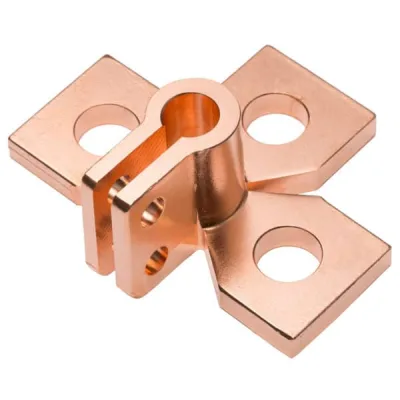

CNC machining - precise machining dimensions with a tolerance of ± 0.01 millimeters and good surface finish.

Inspection and Traceability - Conduct UT, MT, and dimensional testing in accordance with ISO 9001:2015 to ensure consistent quality of gear rings, flanges, and bearing applications.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.