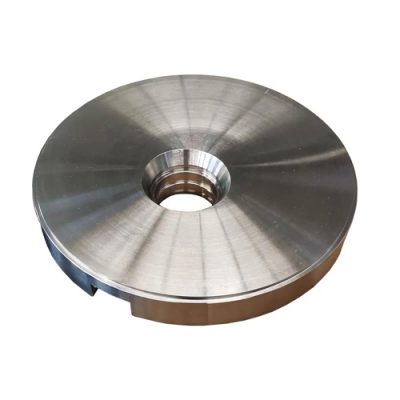

Forged hub assembly

Forged hub components are designed specifically for demanding heavy-duty and high torque applications such as trucks, trailers, and industrial vehicles. Each wheel hub is manufactured using an integrated process of forging, CNC machining, and testing to ensure high strength, precise concentricity, and excellent fatigue resistance.

With advanced processing and customized material options (such as 42) CrMo We provide forged wheel hub components that meet international standards and different customer requirements, including 4140 alloy steel.

Manufacturing process of forged hub assembly

The manufacturing of each wheel hub forging follows a controlled and traceable sequence:

Forging: Alloy steel billets are heated and formed under precisely controlled pressure to obtain a dense microstructure and excellent load-bearing capacity.

CNC Processing: Advanced machining centers ensure perfect hole alignment, precise bearing fit, and smooth sealing surfaces.

Heat treatment: Quenching and tempering can optimize hardness and impact resistance while maintaining dimensional stability.

Surface treatment: The machined surface is treated to prevent corrosion and enhance appearance.

Testing: Ultrasonic and magnetic particle inspection can confirm internal soundness and structural reliability.

This complete workflow ensures the mechanical integrity, precise geometry, and consistency of each production batch.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.