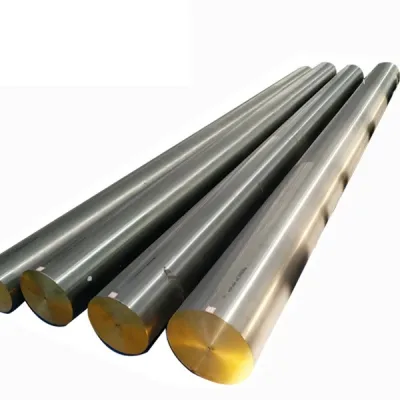

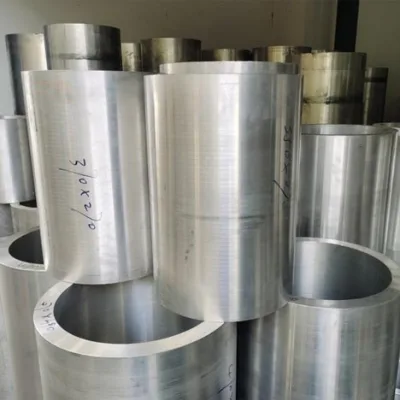

Ring forging

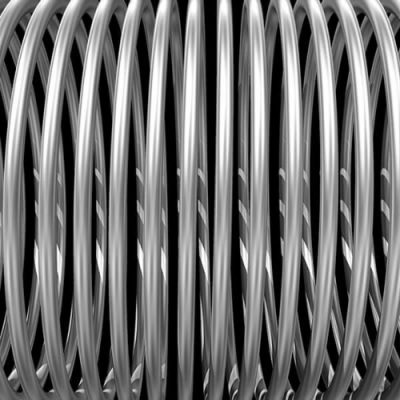

Ring forgings are subjected to pressure processing on the billet through forging machinery.

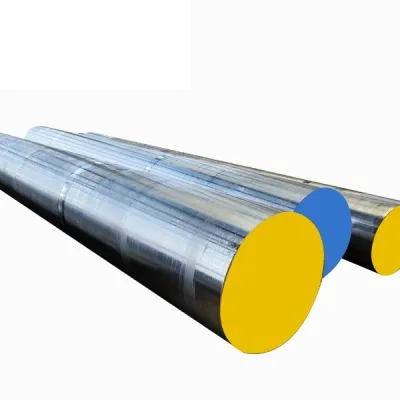

Ring forgings are popular for their excellent mechanical properties, high productivity, material savings, and high production efficiency.

Excellent fatigue resistance, impact and heavy load resistance, high precision requirements, convenient forging operation, and high strength characteristics of annular forgings.

Ring forgings apply pressure to metal billets through forging processes, causing them to undergo plastic deformation and form predetermined shapes, sizes, and properties. This process helps to eliminate pores and voids inside the metal, significantly improving its mechanical properties.

The forging operation relies on the external force exerted by the forging equipment on the billet to ensure that the final obtained annular forging meets the required geometric shape and quality standards.

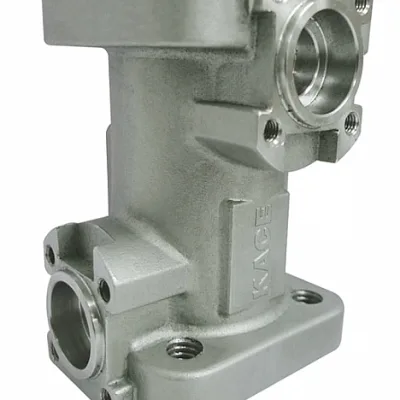

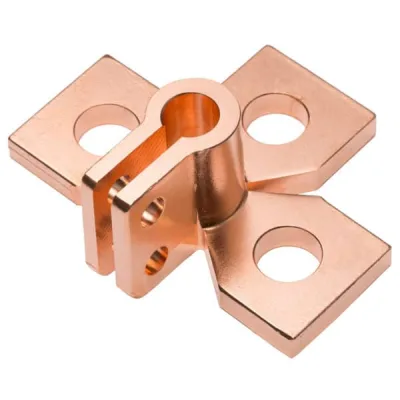

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.