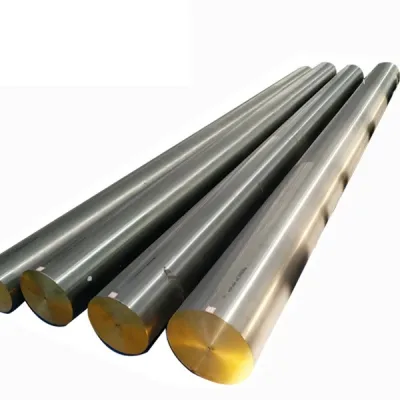

Cold drawn pipe manufacturer

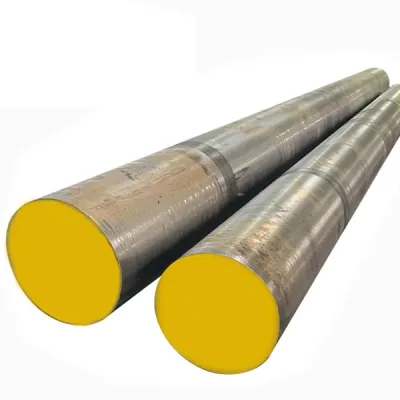

In the metal processing industry, cold drawn pipes are an important industrial material, and their production technology and product quality have received widespread attention. We use specific process technology to cold draw hot-rolled or seamless pipes to produce pipes with higher dimensional accuracy, smoother surface, and better mechanical properties.

Basic principles and characteristics of cold drawing process

*High dimensional accuracy: The cold drawing process is carried out under strict control of the mold, so the outer diameter, inner diameter, and wall thickness tolerances of the pipe can be controlled very accurately, far superior to hot-rolled pipes. This is crucial for mechanical components that require precision assembly.

*Good surface quality: The surface of cold drawn pipes is usually smooth and bright, with fewer defects. However, the surface of hot-rolled pipes has iron oxide scales, which are relatively rough.

*Mechanical performance improvement: The cold work hardening effect during cold drawing can enhance the strength and hardness of the pipe material. Of course, this is sometimes accompanied by a slight decrease in plasticity (such as elongation).

*Can produce thin-walled and small-diameter pipes: Cold drawing process is more suitable for producing pipes with very thin wall thickness or small diameter, which is difficult to achieve with hot rolling process.

The main application areas of cold drawn tube products

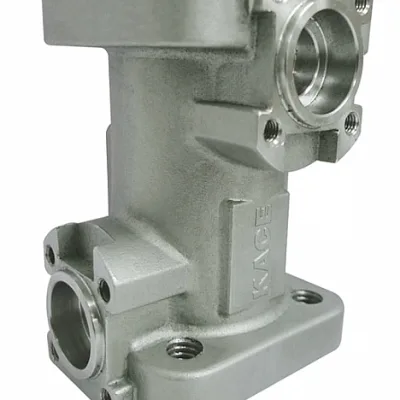

*Mechanical manufacturing: used for producing structural components such as hydraulic cylinders, cylinder barrels, various transmission shafts, and precision instruments. These occasions have strict requirements for the dimensional accuracy, straightness, and surface smoothness of the pipes.

*Automotive industry: applied to shock absorber pipes, steering gear rack pipes, some fuel system pipe fittings, etc.

*Textile machinery: used as a substrate for various rollers and shafts.

*Other fields: such as fitness equipment, furniture components, precision piping for some construction machinery, etc.

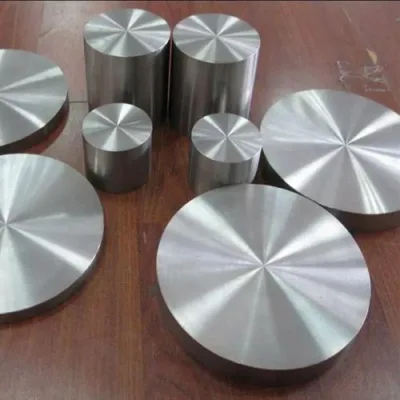

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.