How to improve the quality of large aluminum alloy forgings?

As one of the important industries in our country, the forging industry has made some progress. Our country is relatively advanced in the production of forgings, but according to comparison and analysis, there is still a big gap between our country's forging production and the world level. It needs to be improved and developed from different aspects.

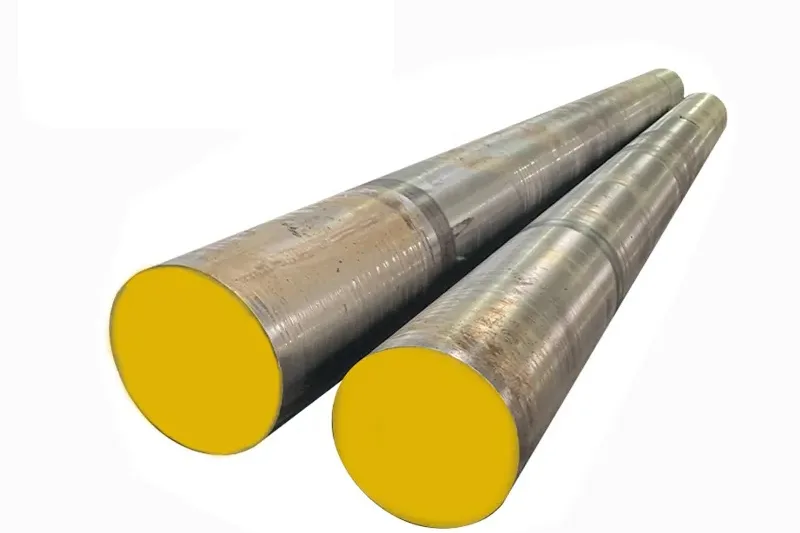

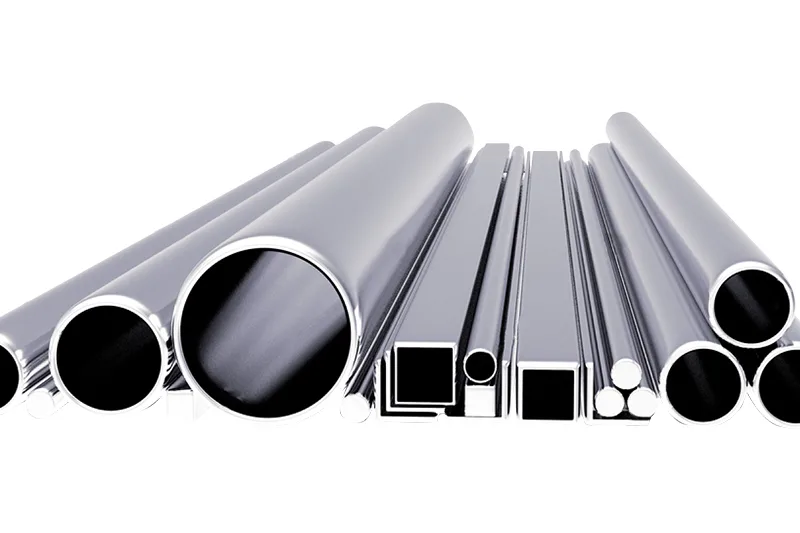

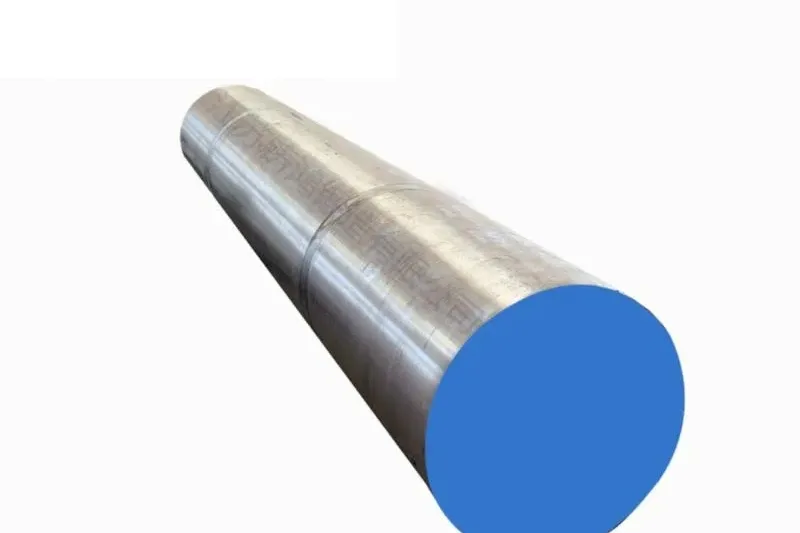

Large forgings are an important part of machinery and equipment, so any equipment will be used, and the manufacturing process is much more complicated than that of ordinary small forgings. Therefore, both the investment in equipment and the formulation of the process are very strict. In addition, the scale of use of large forgings has increased. Once there is a quality problem with the forgings, it will directly affect the development of the project. Therefore, for manufacturers, they must find ways to improve the quality of large forgings.

Methods for lifting large forgings

1. The development of scientific research can provide a good way to improve the quality of forgings. Many problems that occur in the manufacturing process of manufacturers are known through later research. The development of scientific research projects requires a certain amount of funds, so manufacturers can appropriately increase the proportion of scientific research funds. They can not only send company technicians to the laboratory to participate in research, but also invite relevant scientific research experts to the scene to guide the work.

2. Manufacturers must conduct thorough research on forging materials. From the perspective of the entire forging process, the influence of materials is significant.

Recently Posts