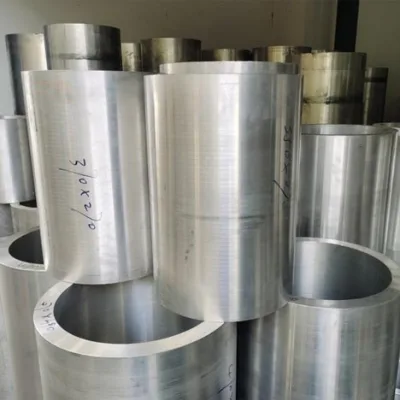

7050 aluminum alloy

7075 aluminum alloy is a high-strength and high hardness aluminum alloy material, belonging to Al-Zn-Mg-Cu It is made of ultra hard aluminum alloy.

It has been widely used in various fields such as aerospace, mold manufacturing, and high-end sports equipment due to its excellent mechanical properties and corrosion resistance. The main alloying elements of 7075 aluminum alloy include zinc, magnesium, and copper. The addition of these elements significantly improves the strength and hardness of the alloy, giving it excellent fatigue resistance and stress corrosion cracking resistance.

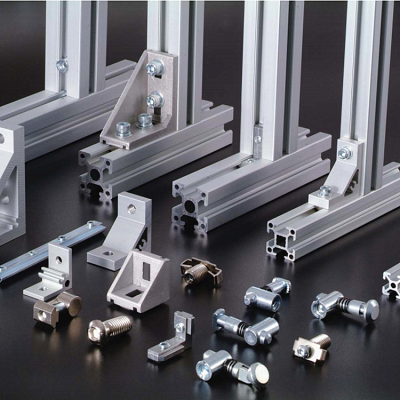

7075 aluminum alloy is particularly suitable for applications that require high loads and stresses due to its high strength and hardness. For example, in the aerospace industry, 7075 aluminum alloy is widely used to manufacture key components such as aircraft structural parts and engine parts. In the field of mold manufacturing, 7075 aluminum alloy has become an ideal material for manufacturing high-precision molds due to its excellent wear resistance and corrosion resistance.

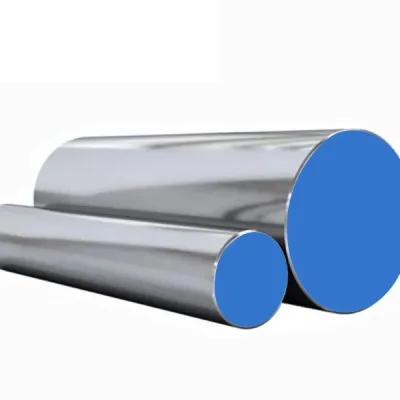

The processing performance of 7075 aluminum alloy is relatively good, and various shapes and sizes of parts and components can be made through various processing methods such as forging, rolling, and extrusion.

We also provide forging blanks and CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.