0Cr13Ni4Mo has the following processing properties:

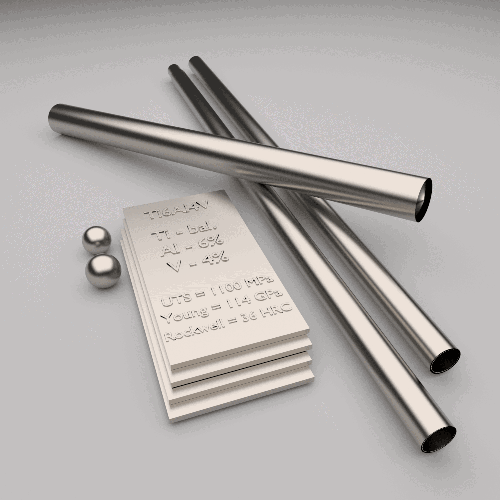

0Cr13Ni4Mo chemical composition:

C≤0.05

Si≤0.60

Mn 0.5-1.0

P≤0.03

S≤0.03

Cr: 11.5-14

Mo: 0.5-1.0

Ni: 3.5-5.5

0Cr13Ni4Mo mechanical properties:

Tensile: ≥790

Yield: ≥620

Elongation: ≥15

Reduction of area: ≥45

Hardness: ≤295

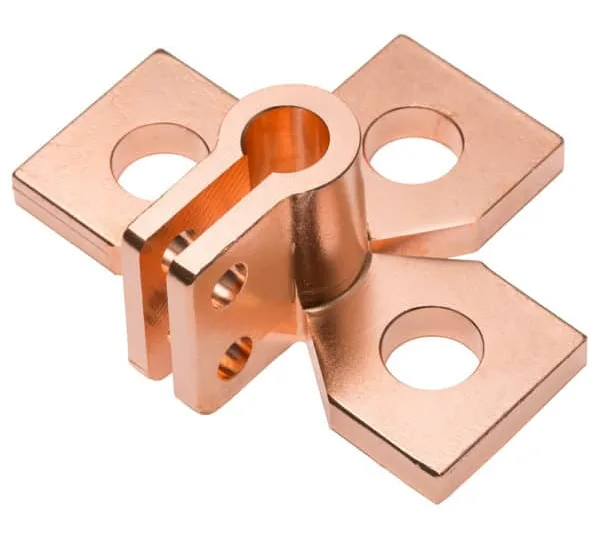

Easy to machine and weld: 0Cr13Ni4Mo material is easy to process, including cutting, drilling, milling, etc. At the same time, it also has good welding performance and can undergo conventional welding processes such as manual arc welding and argon arc welding. This makes the material more flexible and convenient in the production of parts and structures.

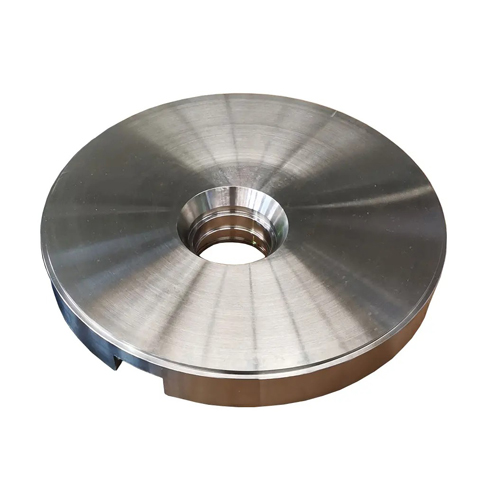

Good plasticity and deformability: 0Cr13Ni4Mo has good plasticity, allowing for deformation into various shapes and sizes through methods such as cold working and hot working. This makes it suitable for processing needs that require complex shapes and special dimensions.

In summary, due to the machinability and good plasticity and deformability of 0Cr13Ni4Mo material, it has certain advantages in the manufacturing of parts and structures of various shapes and sizes.

Recently Posts