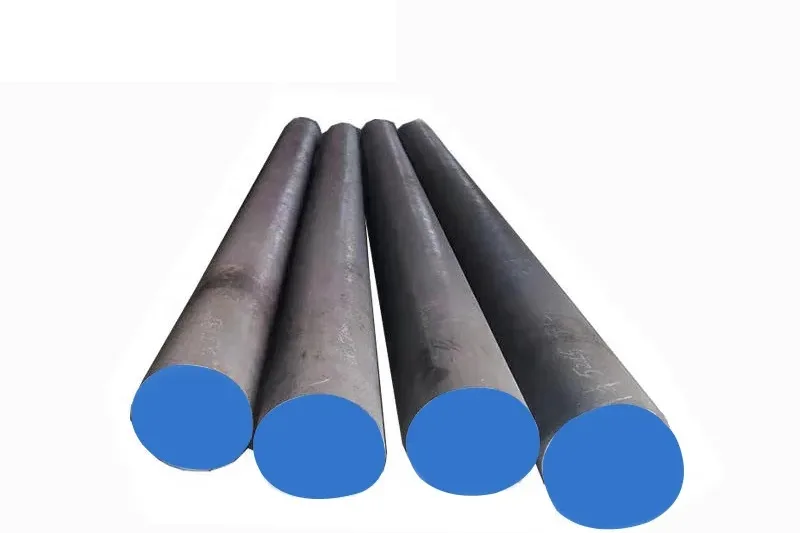

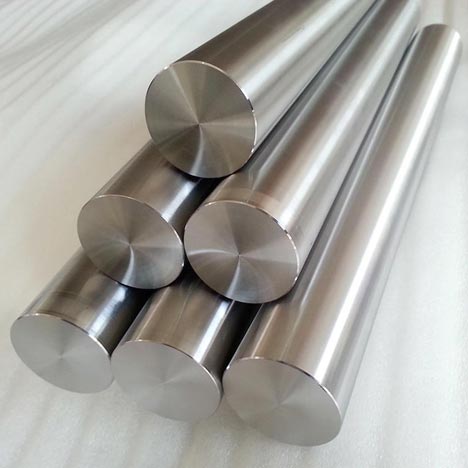

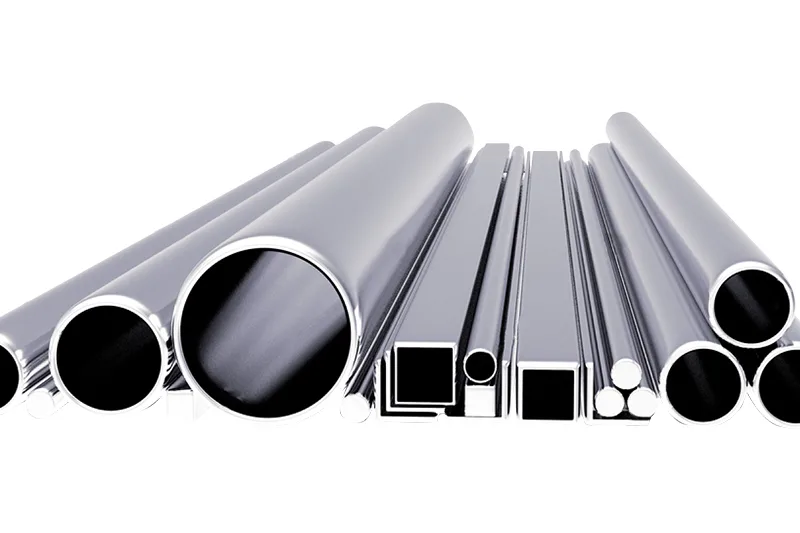

Z33C13 stainless steel high hardness and wear resistance material

Z33C13 is a stainless steel material with high hardness and excellent wear resistance, making it suitable for manufacturing parts that require long-term travel and need to resist wear. The following are the characteristics of Z33C13 in some applications:

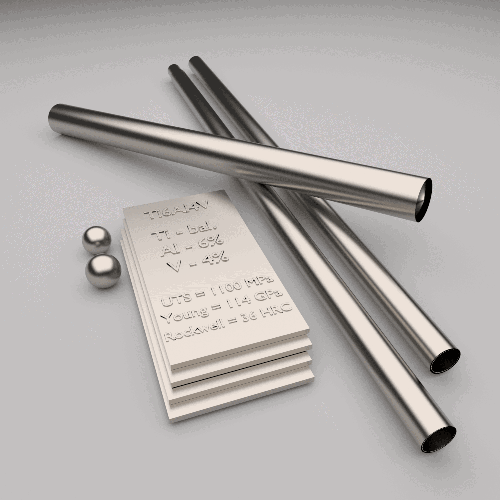

Z33C13 chemical composition:

Carbon C: 0.26~ 0.35

Silicon Si: ≤ 1.00

Mn: ≤ 1.50

Sulfur S: ≤ 0.030

Phosphorus P: ≤ 0.040

Chromium Cr: 12.00~ 14.00

Z33C13 mechanical properties:

Tensile strength (MPa): quenching and tempering, ≥ 800~ 1000

Conditional yield strength of 0.2 (MPa): quenched and tempered, ≥ 600

Elongation delta 5: quenching and tempering, ≥ 10

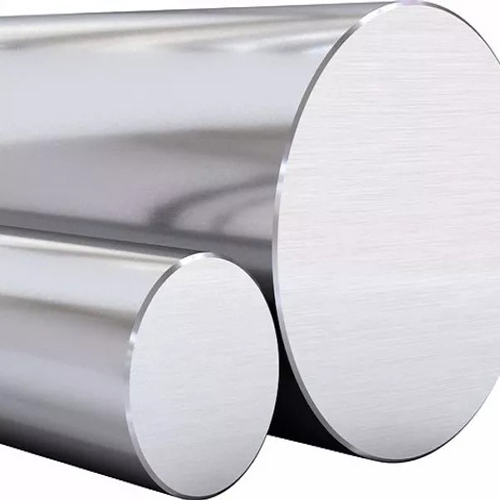

Heat oil pump shaft: Due to its high hardness and wear resistance, Z33C13 can be used to manufacture the working shaft of hot oil pumps. Hot oil pumps are usually used to transport high-temperature lubricating oil or other hot media, and work in constant friction and high temperature environments, so they need to have excellent wear resistance.

Hydraulic valves: In the application of hydraulic valves, Z33C13 can be used to manufacture some parts that need to withstand high pressure and frequent movement. Due to factors such as high pressure fluid impact and sealing friction inside the hydraulic press, the material needs to have excellent wear resistance to ensure long-term stable operation.

Cylinder liners: In the manufacture of cylinder liners for automotive engines or diesel engines, the Z33C13 can be used as a precision component. Since the cylinder liner needs to be sealed and rubbed against the piston, it needs to have wear resistance to ensure long-term use.

Recently Posts