X30Cr13 stainless steel is widely used in the aerospace industry

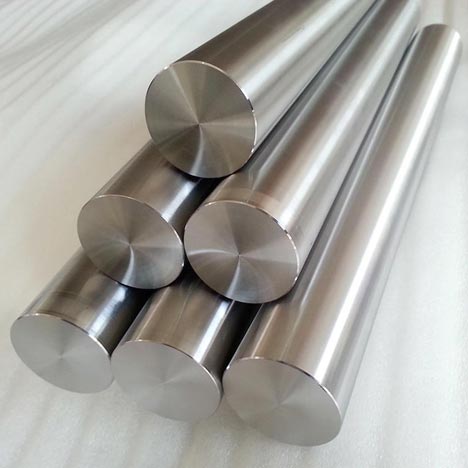

X30Cr13 stainless steel has ultra-mirror machinability, which means it can achieve a very smooth surface, meeting the requirements of high-precision machining. In the annealed state, it also exhibits good machinability. Here is a more detailed description of the characteristics of X30Cr13 stainless steel:

X30Cr13 chemical composition:

Carbon C: 0.26~ 0.35

Silicon Si: ≤ 1.00

Mn: ≤ 1.50

Sulfur S: ≤ 0.030

Phosphorus P: ≤ 0.040

Chromium Cr: 12.00~ 14.00

X30Cr13 mechanical properties:

Tensile strength (MPa): quenching and tempering, ≥ 800~ 1000

Conditional yield strength of 0.2 (MPa): quenched and tempered, ≥ 600

Elongation δ 5: quenching and tempering, ≥ 10

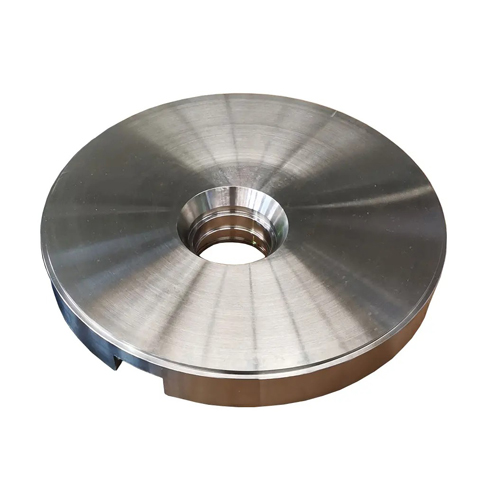

Ultra-mirror processing performance: X30Cr13 stainless steel can achieve a very smooth, mirror-like surface after surface treatment. This makes it ideal for applications that require high-precision processing and appearance requirements, such as optical instruments, touchscreen technology, electronics, etc.

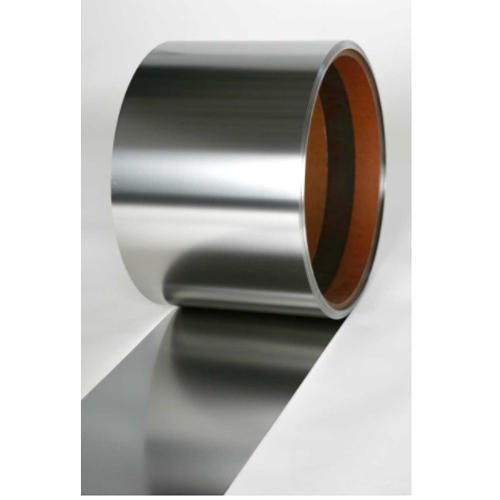

Good machinability in annealed state: When X30Cr13 stainless steel is in annealed state, it has good plasticity and machinability. This makes it easy to perform various machining operations, such as cutting, punching, bending, etc.

Recently Posts