Explore the characteristics and application fields of SUS420J2 stainless steel

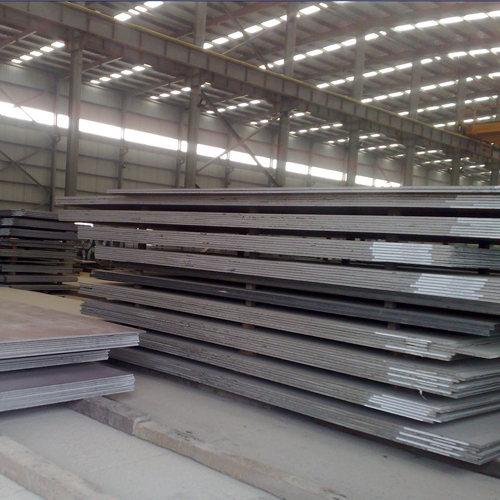

SUS420J2 is a high-grade mirror plastic mold steel, also known as stainless mirror steel. It has the following main properties and characteristics: Excellent Polishing: SUS420J2 has good polishing properties and can achieve a high quality surface finish. This makes it widely used in mold manufacturing, plastic injection and other fields to ensure the aesthetics and fineness of product appearance.

SUS420J2 chemical composition:

Carbon C: 0.26~ 0.35

Silicon Si: ≤ 1.00

Mn: ≤ 1.50

Sulfur S: ≤ 0.030

Phosphorus P: ≤ 0.040

Chromium Cr: 12.00~ 14.00

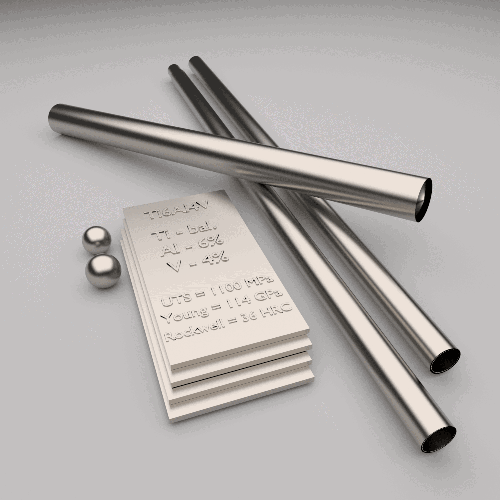

Mechanical properties of SUS420J2:

Tensile strength (MPa): quenching and tempering, ≥ 800~ 1000

Conditional yield strength of 0.2 (MPa): quenched and tempered, ≥ 600

Elongation delta 5: quenching and tempering, ≥ 10

Corrosion resistance: SUS420J2 has excellent corrosion resistance and good resistance to some common corrosive media and gases. This makes it suitable for applications that work in harsh environments or require contact with chemicals.

Wear resistance: SUS420J2 is a stainless steel material with good wear resistance, which can maintain good performance in the case of friction, wear and scratch. Therefore, it is often used to make molds and tools that require wear resistance.

Heat treatment stability: SUS420J2 has good heat treatment stability, and its hardness and strength can be improved by appropriate heat treatment processes. This allows it to achieve higher performance requirements in the fields of mold manufacturing and industrial cutting tools.

Machinability: SUS420J2 has good machinability in annealed state and is easy to perform machining operations such as cutting, forging, grinding and stamping. This makes it widely used in die making and tooling.

Recently Posts